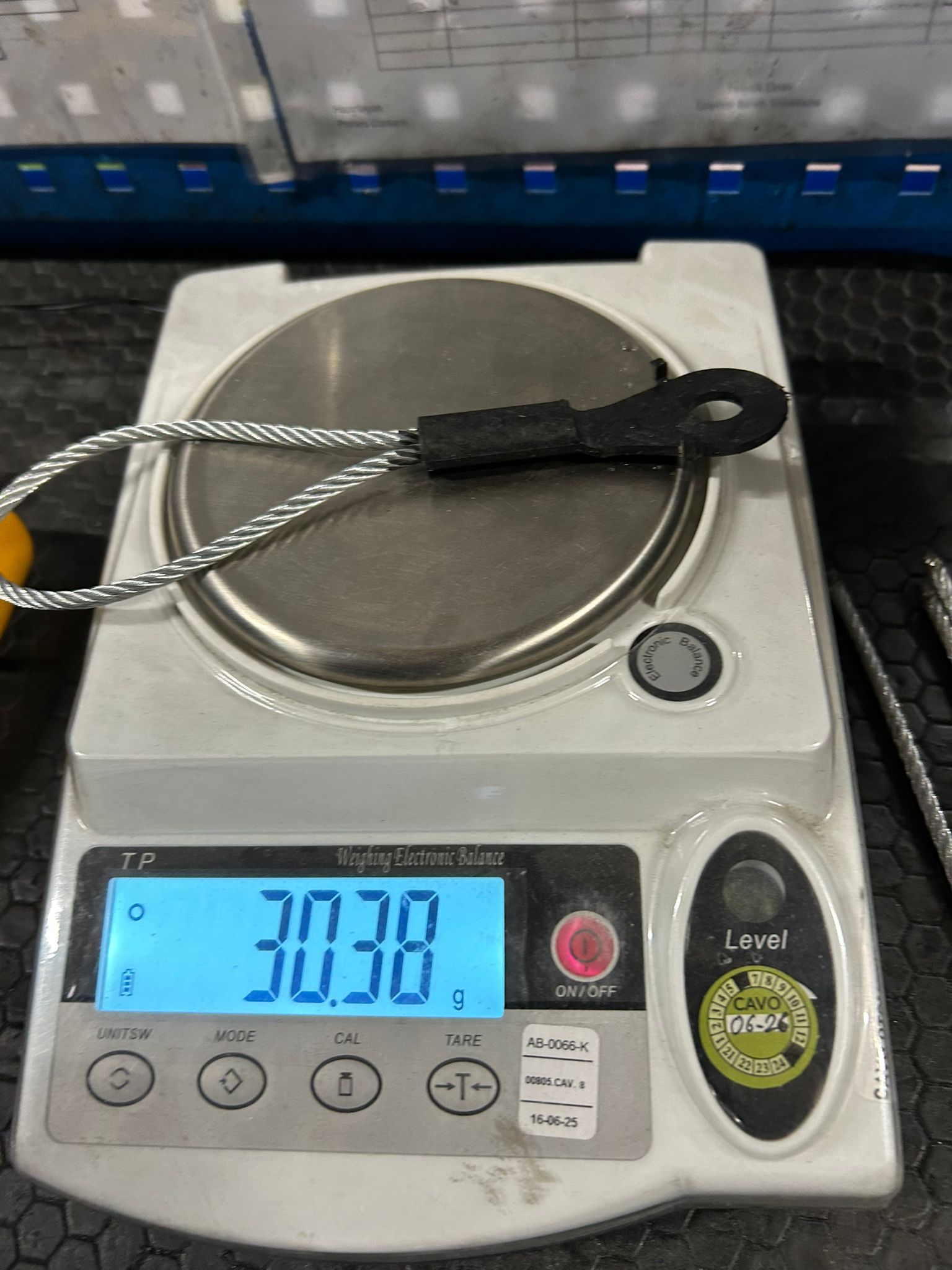

In this project, PA12 filled with 40% long carbon fiber (PA12-LCF40) was chosen to replace traditional metal material for the end fitting of a wire rope. The component, a black end terminal with a circular hole for connection, required excellent strength, durability, and weight reduction.

Wire rope end fittings are traditionally manufactured from metal due to their high load-bearing requirements. However, this often results in excessive weight and corrosion issues in outdoor or marine environments. The client was seeking an advanced solution with a balance of mechanical performance, lightweight, and resistance to harsh conditions.

PA12-LCF40 demonstrated the following key advantages:

By switching to PA12-LCF40, the customer gained a high-performance part that not only met safety and load-bearing demands but also delivered lighter weight and enhanced durability. This solution improved ease of handling and installation while reducing long-term maintenance costs.

This project highlights the successful replacement of a conventional metal wire rope end fitting with a PA12-LCF40 composite material. It reflects the growing trend of "plastic instead of steel" solutions, demonstrating that long fiber reinforced composites can deliver performance and reliability equal to, or surpassing, traditional materials in demanding applications.

Contact Us for Solutions