商品番号。:

PPA-NA-LGFお支払い:

T/T or L/C (other payment ways also can be di製品の起源:

Xiamen, China色:

Original color (also can be customized)出荷ポート:

Xiamen, China商品情報

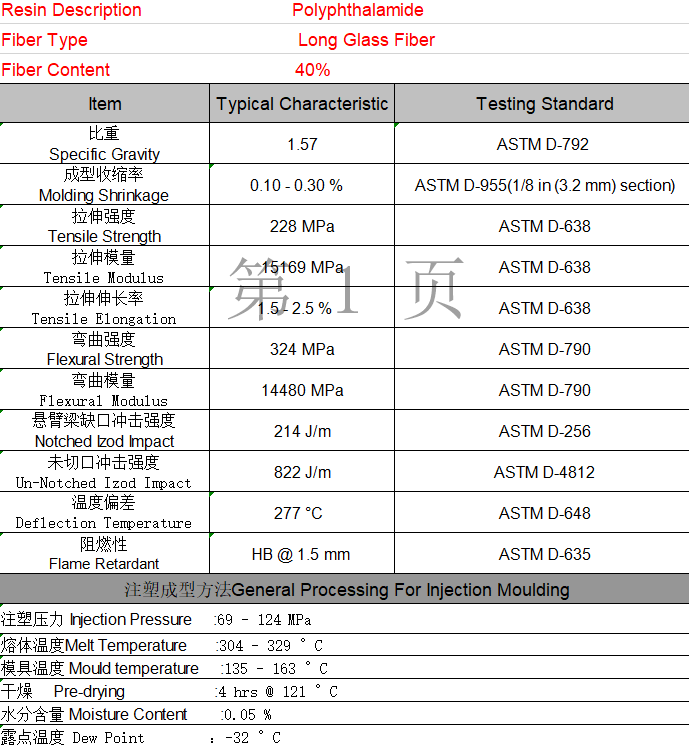

変性ポリp-ベンゾイル-p-フェニレンジアミン (PPA) プラスチックの熱変形温度は最大 300℃、連続使用温度は最大 170℃ で、短期および長期の熱性能のニーズを満たすことができます。強度、硬度、耐疲労性、耐クリープ性などの優れた機械的特性を、幅広い温度と高湿度で維持します。強化された Lv PPA は、優れた靭性と特定の範囲の硬度と柔軟性を組み合わせており、使い捨て剛性のファスナー要件、および屈曲の良い選択の繰り返し使用に適しています。特殊グレードの製品は、スプレーおよび電気メッキの表面、耐火性、耐グリコール性、および反射用途にも利用できます。

特性

☆PPA strength, toughness and hardness superior performance, as well as its good heat resistance, chemical resistance and cracking resistance

☆PPA can maintain strength and hardness in high temperature and high humidity environment, and can be used to replace metal in traditional nylon and polyester

☆PPA plastic also has superior surface gloss. It can be colored instead of sprayed, thus helping to reduce the appearance of scratches and scrapes on the surface.

☆PPA plastics also have good machinability and allow short injection cycle time

Compared with PA46:

√PPA has higher thermal stability than PA46.

√PPA has better CTI/ arc resistance and infrared co-current ability than PA46;

√PPA has better chemical resistance than PA46;

Application

☆ Automotive components, including fuel, transmission and engine systems, reduce weight, cost and provide long service life;

☆ Chipset and socket, cup body welding support;

☆ Chip capacitor, switch and miniature horn, high density printed circuit board connector;

☆ For wear requirements of high occasions, such as no lubrication bearing, seal, bearing isolation ring and reciprocating open compressor parts;

☆ Connectors, controllers, sensors, motors and other key electronic parts

The vast majority of PPA resins are processed by traditional injection molding.

The PPA raw materials are pre-dried to a humidity level of less than 0.1% and then packed into heat-sealed metal village bags or boxes. These containers ensure that PPA raw materials do not need to be dried before processing.

The acceptable humidity level for the process is 0.15% or lower. Wet processing resin can reduce molecular weight, resulting in the loss of mechanical properties.

Using a desiccant bucket dryer, it is easy to dry the resin to a dew point of 25°F or lower at 175°F. Drying time depends on the absorption of water, generally within the range of 4-16 hours.

Injection molding melting temperature in the range of 615-650°F, the material in the barrel of the stay time is not more than 10 minutes, so that the product out of the injection molding mechanical performance is the best.

A mold temperature of at least 275°F is required for complete crystallization and optimal dimensional stability.

Parts with partially thick walls can be injected at lower die temperatures due to slow cooling.

金型温度は、完成品の表面感を最適化するために非常に重要です。

真空金めっき金属用のミネラル フィラー グレードの PPA 樹脂の金型表面温度は、350°F である必要があります。

詳細

色と長さは、必要に応じてカスタマイズできます。

ご不明な点がございましたら、お問い合わせください。