商品番号。:

HDPE-NA-LGF20お支払い:

T/T or L/C (other payment ways also can be di製品の起源:

Xiamen, China色:

Original color (also can be customized)出荷ポート:

Xiamen, ChinaHDPE Introduction

Poor mechanical properties, poor air permeability, easy to deformation, easy to aging, easy to brittle, brittle than PP, easy stress cracking, low surface hardness, easy to scratch. Difficult to print, when printing, surface discharge treatment is required, can not be plated, and the surface is not glossy.

HDPE-Long glass fiber

Because of its high crystallinity, poor impact strength and environmental cracking resistance and other defects, limiting its scope of application, so a lot of toughening modification HDPE research work has been carried out at home and abroad. Our company has greatly improved the performance of HDPE through the way of co-blending modification.

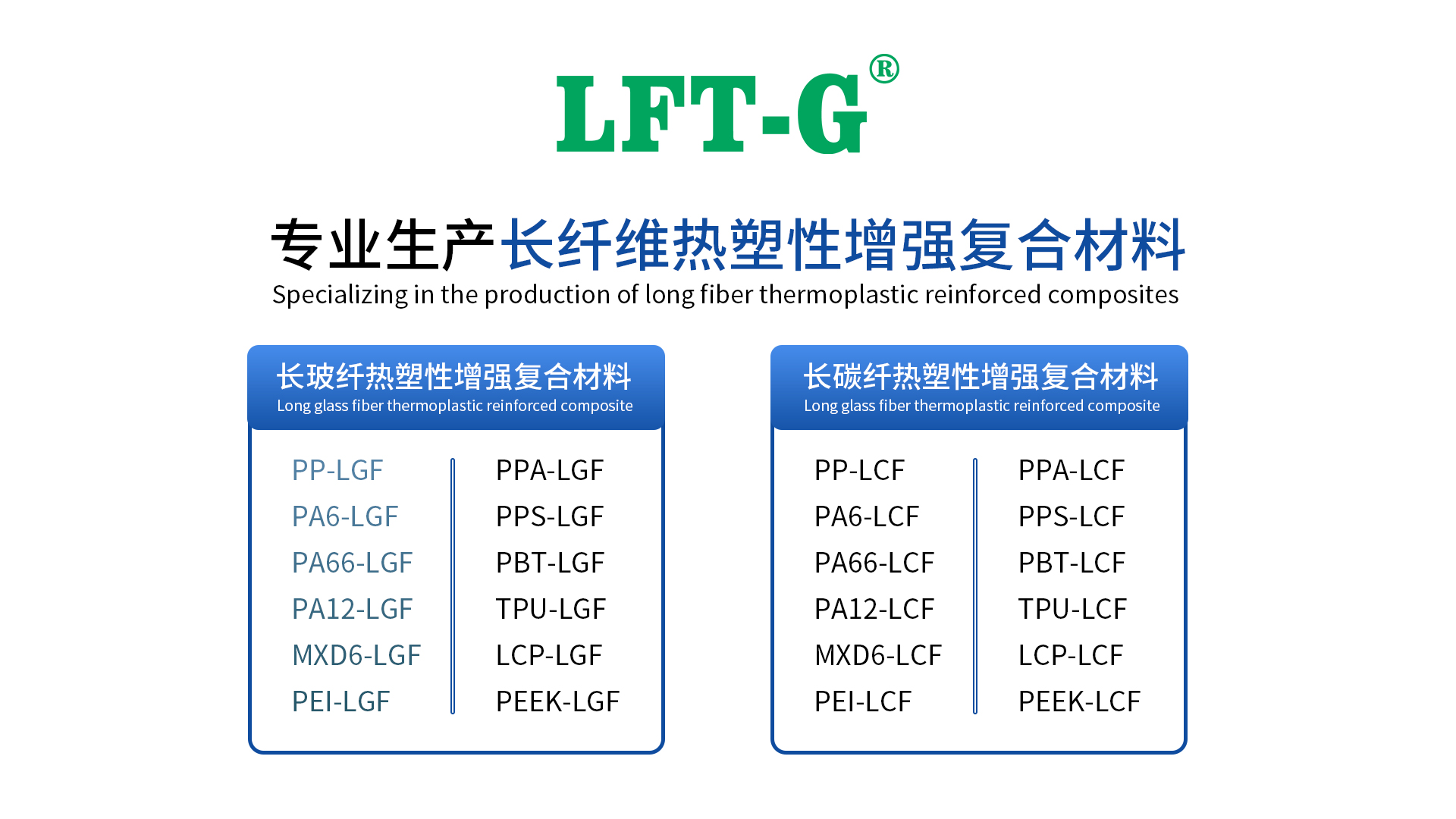

Long fiber reinforced thermoplastic composites are reinforced thermoplastics with fiber lengths greater than 10mm. The reinforcing fibers are mainly glass fibers, carbon fibers, etc. Depending on the type of resin with appropriate fiber surface treatment, better results can be achieved.

The addition of fiber material to the resin can greatly improve the overall material performance. Fiber composites absorb external forces in three ways: fiber pullout, fiber breakage, and resin fracture. The increase of fiber length consumes more energy for fiber pull-out, which is beneficial to the improvement of impact strength; the end of fiber in the composite is often the initiation point of crack growth, and the small number of long fiber ends also makes the impact strength increase; the long fiber blends entangle, flip and bend each other when filling the mold, unlike the short fiber blends which are arranged in the flow direction, therefore, the long fiber blends molded products are better than the same molded parts of short fiber blends. Therefore, compared with the same molded parts of short fiber blends, the long fiber blends have higher isotropy, better straightness, less warpage, and therefore better dimensional stability; the heat deflection temperature of long fiber reinforced thermoplastics is also increased than that of short fiber blends. Therefore, long-fiber composites exhibit better performance than short-fiber composites, which can improve rigidity, compression strength, bending strength, and creep resistance.

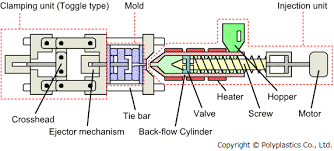

プロセス

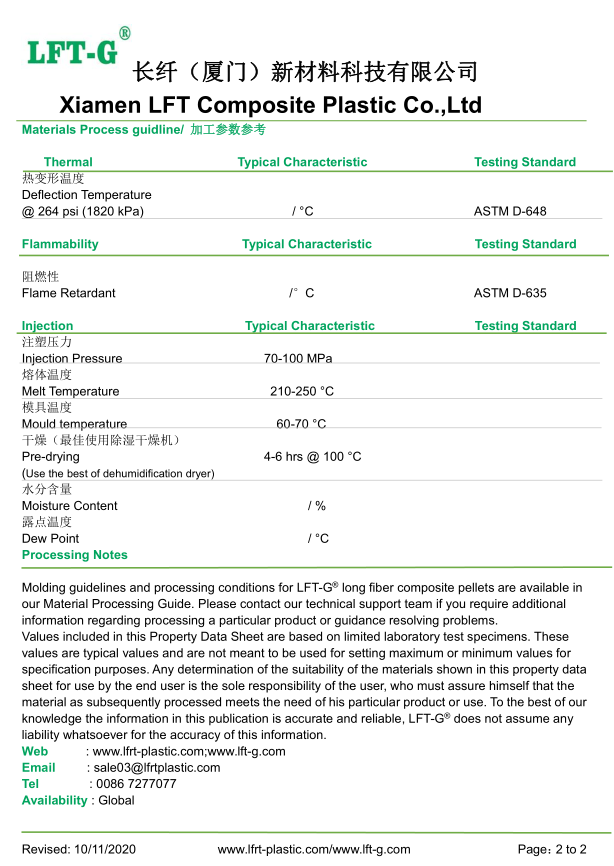

ご参考までにTDS

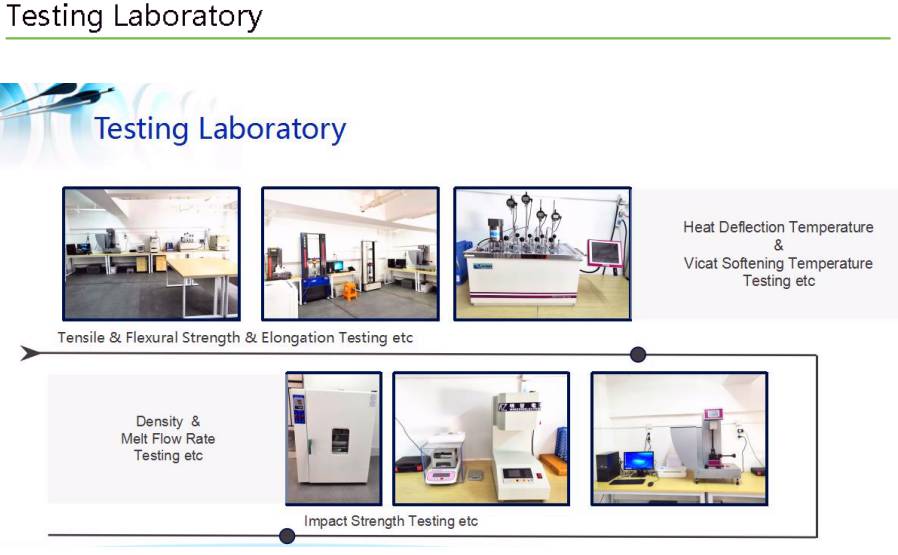

テスト

認証

品質マネジメントシステム ISO9001/16949認証取得

国立研究所認定証明書

変性プラスチック革新企業

名誉証明書

重金属のREACHおよびROSH試験

応用

お客様の製品イメージに基づいて技術サポートを提供いたします。

私たちに関しては

私たちはあなたに以下を提供します:

1. LFT & LFRT 材料技術パラメータと最先端の設計。

2. 金型のフロント設計と推奨事項。

3. 射出成形、押出成形などの技術サポートを提供します。

よくある質問

Q: 長繊維強化熱可塑性材料を使用する場合、補強方法と材料の長さをどのように選択すればよいですか?

A: 材料の選択は製品の要件によって異なります。製品の要求性能に応じて、内容物をどの程度強化するか、どの程度の長さが適切であるかを判断する必要があります。

Q: 長繊維製品は射出成形に適しているだけでなく、押出成形などの加工も可能ですか?

A: LFT 長ガラス繊維と長炭素繊維は主に射出成形に使用され、また、さまざまな熱可塑性プラスチック成形方法でプレート プロファイル チューブやモールド エッジを押出成形することもできます。

Q: 長繊維製品は原材料に比べてコストが高くなります。リサイクル価値は高いですか?

A: 熱可塑性 LFT 長繊維素材はリサイクルして再利用することができます。