商品番号。:

PPS-NA-LCFお支払い:

Discussed製品の起源:

China色:

Natural color or Customized出荷ポート:

Xiamenリード タイム:

2-10 working days

PPS plastic (polyphenylene sulfide), is a thermoplastic special engineering plastic with excellent comprehensive properties. Its outstanding features are high temperature resistance, corrosion resistance and superior mechanical properties. The product will make a metallic sound when it is dropped to the ground. .

Pure PPS is rarely used alone due to its brittle performance. Most of the PPS used is its modified variety. Glass fiber reinforced PPS is one of them.

PPS lengthened glass fiber (LGF) composite material has the advantages of high toughness, low warpage, fatigue resistance, and good product appearance. It can be used in water heater impellers, pump casings, joints, valves, chemical pump impellers and casings, cooling water impellers and Shells, home appliance parts, etc.

What Are the Applications of PPS Long Fiber Reinforcement?

Engineering PlasticsAutomotive industry Applications:

Due to its excellent mechanical properties, thermoplastic carbon fiber is widely used in the automotive field of fuel system components, sensors, shell components. On the one hand, it is because of the high strength and stiffness of PPS-LCF, and the finished parts are not easy to damage. On the other hand, PPS-LCF also has a relatively low coefficient of thermal expansion to ensure the stability of the finished product. In addition, PPS-LCF also has very good corrosion and heat resistance, making the application life of the finished product longer.

Industrial Applications:

In the industrial field, it is mainly used in the parts of equipment, such as chemical processing equipment, air pumps, gaskets, valves, etc. In addition to the high strength of the PS-LCF, it is also because the parts made by the PS-LCF have very good self-lubricating properties, which is very important for mechanical parts. Therefore, compared with the traditional carbon fiber material products, the performance has been greatly improved.

The wide range of applications of PPS-LCF include aerospace, automotive manufacturing, electronic equipment, chemical and medical fields.

For a long time, polyamides have been the material of choice for electrical connectors. This is because electrical connectors, as well as other non-conductive electrical parts, require high heat resistance which polyamide can offer. Polyamide is also chosen due to its low cost, easy formability, high strength, and electrical insulation properties.

Difference between PPS and PPA

Although PPS and PPA are both high-performance engineering plastics, there are still clear differences between them in some aspects:

1. chemical structure is different: the main chain of PPS contains sulfur atoms, and the main chain of PPA contains amide groups, which determines their differences in physical properties and chemical properties.

2. different heat resistance: although both have excellent heat resistance, but the high temperature resistance of PPS is more prominent, can be used at higher temperatures for a long time.

3. mechanical properties difference: PPA high temperature nylon than PPS material mechanical properties are better, with higher tensile strength (23°C to 200°C) and higher weld strength.

4. dimensional stability and flame retardant difference: PPS water absorption is very low, has better dimensional stability than PPA; PPS flame retardant has more advantages, PPS has self-extinguishing, its flame retardant can reach UL94 V-0 level.

FAQ

*What processes are LFT materials suitable for?

LFT material is mainly suitable for injection molding, as well as partial extrusion. The requirements for injection molding machines are mainly reflected in the nozzle.

*Why are your products so long? Why does the material I used before, filled with glass fiber, look different than this?

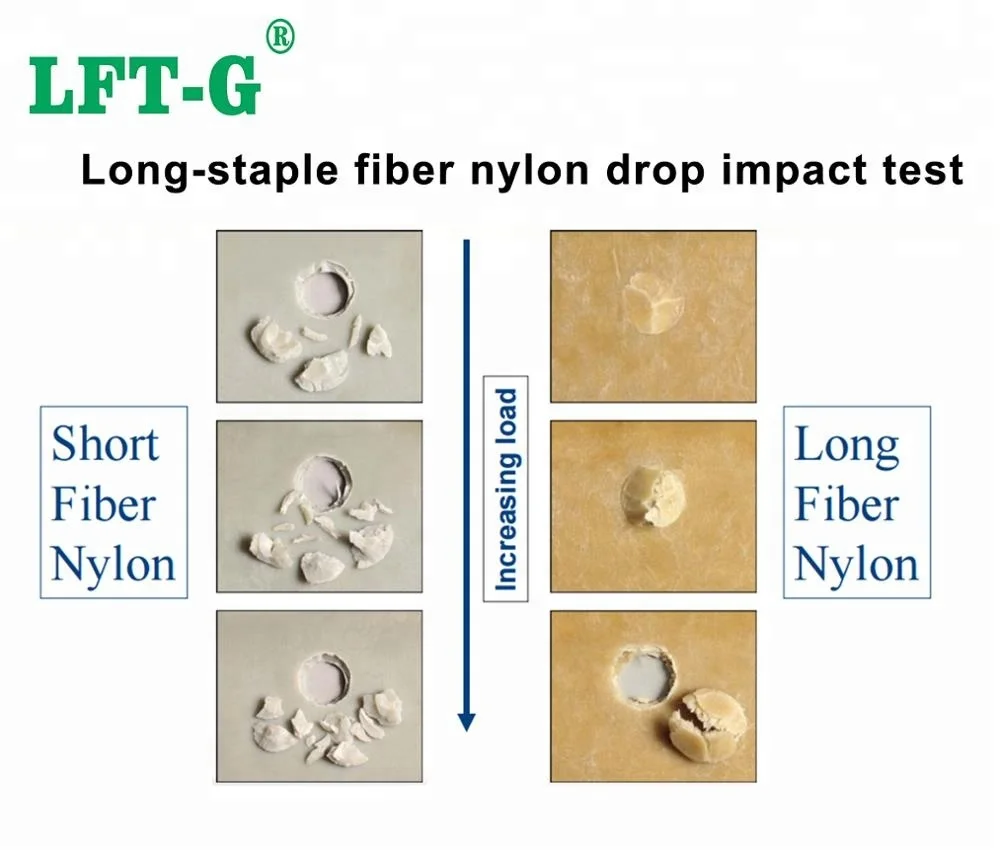

Although long fiber modified materials (LFT) and short fiber modified materials (SFT) are through the combination of fiber and resin to produce higher properties of the complex. However, the two materials are different from the production process, internal structure, appearance, performance, application and so on.

Production process: The fiber of SFT is chopped and mixed with resin, and the production process of LFT is melt impregnation.

Internal structure: The fibers inside SFT particles are short and disordered, while the fibers inside LGF are neatly arranged and longer.

Appearance: The length of SFT is usually less than 3 mm, and the length of LFT is 5-24mm.

Performance: LFT impact performance than SFT increased 1-3 times, tensile strength increased by more than 50%, mechanical properties improved by 50-80%.

Application: LFT is more suitable for use in products with high strength requirements, as load-bearing parts and structural parts.

*What is your MOQ?

MOQ is 25kg

*Do you support custom service?

Color: Please let us know which Pantone color you want to customize

Length: Lengtjh between 5mm-24mm can be customized. If there are no special requirements, the length of the plastic particles is 10-12 mm.

Our custom service is free, but the MOQ is 500kg.

*Where is your factory?

現在、弊社の本社と工場は中国の厦門にあります。

また、中国の他の省にもいくつかのオフィスがあり、トルコには独占代理店があります。