品番:PA6-NA-LCF40

製品繊維: 20%-60%

製品用途: ヘルメット、車のバンプ、ロボット、アームなどの製造に適しています。

製品の特徴:高靭性、軽量、高強度、耐摩耗性、耐食性、耐クリープ性、伝導性、伝熱性。

品番:PA6-NA-LCF40

製品繊維: 20%-60%

製品用途: ヘルメット、車のバンプ、ロボット、アームなどの製造に適しています。

製品の特徴:高靭性、軽量、高強度、耐摩耗性、耐食性、耐クリープ性、伝導性、伝熱性。

商品番号。:

PA6-NA-LCF40お支払い:

T/T or L/C (other payment ways also can be di製品の起源:

Xiamen, China色:

Original color (also can be customized)出荷ポート:

Xiamen, China商品情報

ナイロン 6 (PA6) には、高い機械的強度、優れた靭性、優れた圧縮性能、優れた耐疲労性、耐クリープ性などの利点があります。非金属パイプの圧力材料として使用して、非金属パイプの変形を効果的に防ぎ、パイプの外部押しつぶしに抵抗することができます。

長炭素繊維(LCF)は、高強度、高弾性率、比表面積と長径比が大きく、導電率が高いなどの特徴があります。CFとPA6を組み合わせることで、PA6の機械的特性をさらに向上させることができます。

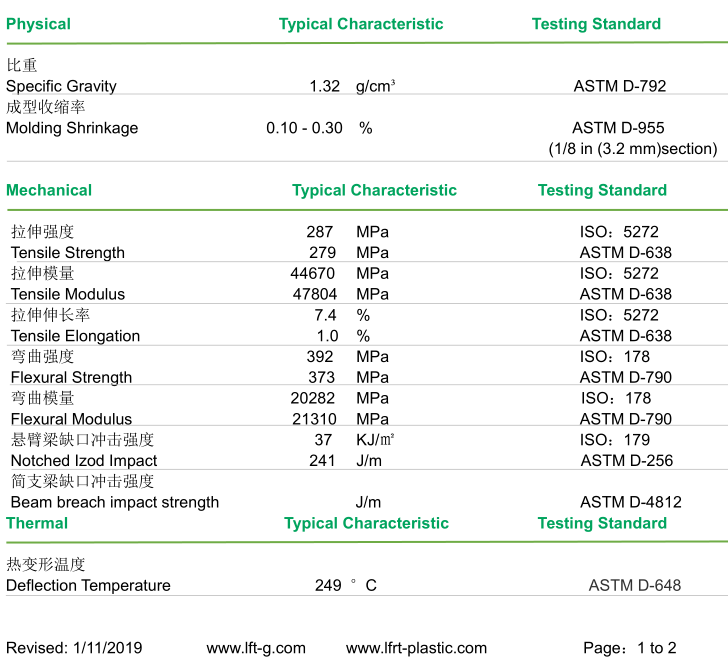

製品データシート

データシートは、参照用として当社独自のラボで作成されています。

製品の利点

1.軽量・高強度

The density of carbon fiber reinforced resin matrix composites commonly used in automobiles is 1.5 ~ 2.0g/cm3, only ordinary carbon steel 1/4 ~ 1/5, lighter than aluminum alloy about 1/3, and the mechanical properties of carbon fiber composites are better than metal materials, its tensile strength is 3 ~ 4 times higher than steel, stiffness is 2 ~ 3 times higher than steel, fatigue resistance is 2 times higher than steel. The weight is 3 ~ 4 times lighter than steel, and the coefficient of thermal expansion is 4 ~ 5 times smaller.

In terms of specific strength, carbon fiber composite is much stronger than carbon steel, and can exceed some special alloy steel, so it has a higher specific strength.

2. Good designability

The designability of carbon fiber composite is very strong, and it can be flexibly designed according to different application requirements. According to the stress condition of the product structure, the structure and arrangement of the fibers can be adjusted to make anisotropic and different thickness products, and the sandwich structure can be used to improve the overall rigidity of the components, so as to achieve the best lightweight design scheme.

By arranging the carbon fiber according to the force direction, the anisotropy of the strength of the composite can be brought into full play so as to save materials and reduce weight. However, due to the isotropy of metal materials, there will be excessive strength in the other direction after meeting the technical requirements of the maximum force direction.

For the products with corrosion resistance requirements, the matrix resin and reinforcement materials with good corrosion resistance can be selected in the design, while for some other performance requirements, such as dielectric properties, heat resistance, etc., can be met by choosing the appropriate raw materials. In addition, in order to make the product cost reach an acceptable degree, the replacement of low-cost materials can be appropriately selected, such as the mixed layup of different fibers, which can meet the component performance index and save the material cost.

3. Integration of parts

Composite material in the forming of its fluidity, easier to make a variety of shapes of the surface, to achieve an integrated molding effect. Therefore, composite materials are suitable for making automobile parts which are difficult to manufacture, low production efficiency and difficult to ensure accuracy.

For example, Lotus sports car aims to use carbon fiber material for the whole vehicle, and makes the body parts lightweight and integrated, which not only reduces the weight of the body, but also greatly increases the stiffness and strength of the parts and improves the performance of the whole vehicle.

4. Resistance to impact

The impact resistance of carbon fiber composites is also good. The carbon fiber composites based on polymer matrix have certain viscoelastic mechanical properties and can absorb certain impact energy.

5. Good corrosion resistance

Carbon fiber composite products generally do not have rust and corrosion problems. Polymer matrix composites have excellent acid resistance, seawater resistance, alkali, salt and organic solvent resistance.Therefore, it is an excellent corrosion resistant material.

Product application

Early carbon fiber composites were mainly used in the military. With the improvement of material properties, forming technology and the decrease of price, carbon fiber composites are more and more applied to the general industry and sports and leisure fields.

Driven by the global trend of energy saving and environmental protection, the problem of automobile fuel consumption has attracted more and more attention. Lightweight design has become an effective way of automobile energy saving and emission reduction, and the material performance and development trend of carbon fiber composite materials are in line with the development needs of the automobile industry. With the development of new energy vehicles, carbon fiber composite materials will be more and more widely used in automobiles.

Besides, it is also suitable for manufacturing helmets, car bumps and robotic arms etc.

Contect us

アモイLFT複合プラスチック有限公司は、20年間エンジニアリングプラスチックの改質を専門としています。新素材、新技術、ひとつひとつの素材を丁寧に行います。当社は、お客様のニーズに合わせて材料をカスタマイズできます。20年以上の技術経験の蓄積により、私たちは信頼できる変性材料メーカーです。お問い合わせへようこそ。カスタマイズされたソリューションと無料の見積もりを提供できます。

電子メール: sale02@lfrtplastic.com

連絡先番号: 13950095727