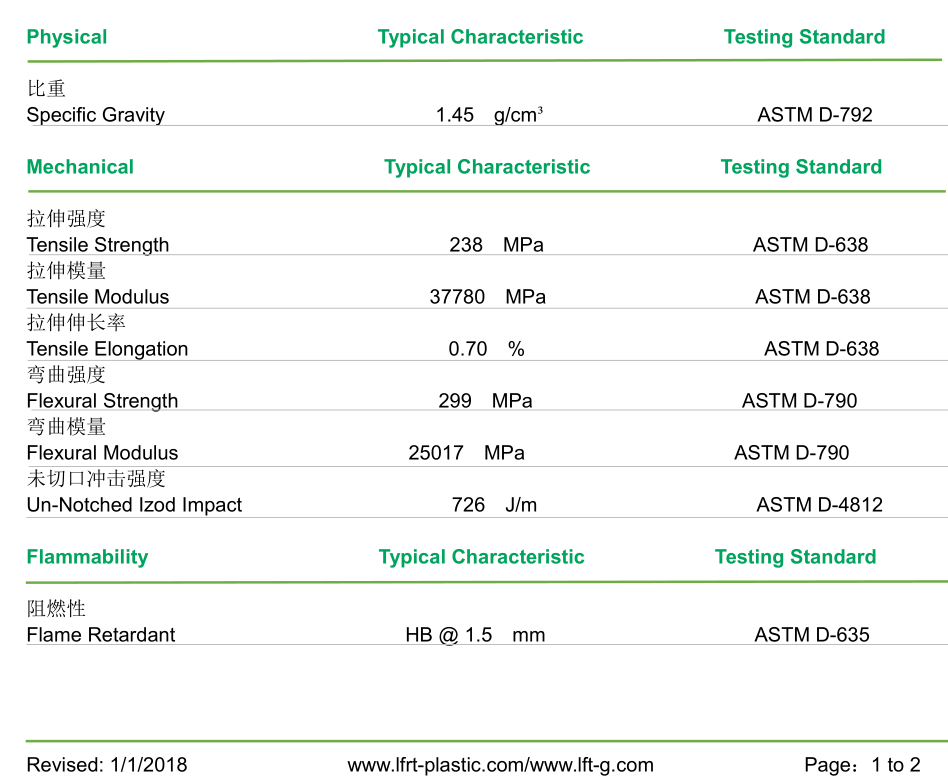

商品番号。:

PEEK-NA-LGF30お支払い:

T/T or L/C (other payment ways also can be di製品の起源:

Xiamen, China色:

Original color (also can be customized)出荷ポート:

Xiamen, ChinaPEEK-NA-LGF30

PEEK LGF30 is PEEK filled with long glass fiber plastic. Due to the long glass fiber, the biggest difference between PEEK LGF30 and PEEK pure plastic lies in modulus. The modulus value of PEEK LGF30 is 6300mpa, which is the highest in the PEEK family. PEEK LGF30 has higher stiffness and wear resistance, and correspondingly higher stiffness makes the plastic more brittle.

Characteristics

Low friction coefficient

PEEK LGF30 has a 5% elongation at break and a particularly smooth surface with low surface coefficient, making it suitable for applications requiring rigid friction rather than impact.

Low deformation temperature

More importantly, due to the addition of glass fiber, the deformation of PEEK LGF30 is lower than that of pure PEEK material under the same high temperature and high pressure. When the temperature exceeds the glass transition temperature of PEEK at more than 150℃, the glass state of the material will occur. In this case, recrystallization will occur, which will correspondingly reduce the mechanical strength of PEEK material. However, the recrystallization rate of PEEK LGF30 will be reduced due to the presence of glass fiber. Therefore, if the pure PEEK material and PEEK LGF30 are subjected to the same high temperature and high pressure working conditions, the deformation temperature of PEEK LGF30 will be lower.

PEEK is one of the existing thermoplastic materials with the best heat resistance. The melting point is 343℃, and the UL certified long-term use temperature is 260℃. Even when the temperature reaches 300℃, it can still maintain excellent mechanical properties. PEEK thermal deformation temperature is 135~160℃, 20% glass fiber reinforced PEEK thermal deformation temperature is 286℃, 30% glass fiber reinforced thermal deformation temperature is 300℃.

Good Mechanical ability

PEEK has excellent mechanical properties and is the most perfect combination of toughness and rigidity among all resins. PEEK has high rigidity, and its strength and fatigue resistance can be compared with some metals and alloy materials. It can maintain high strength even at high temperature. The bending strength can reach 24MPa at 200℃, and the bending strength and compressive strength can reach 12-13 MPa at 250℃, which is especially suitable for manufacturing components that work continuously at high temperature.

PEEK has low linear expansion coefficient (close to aluminum) and good dimensional stability. In addition, PEEK also has good creep resistance, can withstand great stress during the service life, and will not be significantly extended due to the extension of time.

Why is PEEK so expensive?

01 Monomer materials are expensive:

The two main monomers of PEEK polymerization, 4,4 '-difluorophenone and hydroquinone, are expensive. In addition, there are relatively high requirements on the particle size and purity of sodium salt used.

02 Harsh reaction conditions and high cost:

The PEEK polymerization process must ensure the reaction in the state of oxygen, and the reaction temperature is as high as 310-340℃. In order to obtain a higher purity PEEK resin, it is necessary to carry out dozens of times of alcohol exquisite process and washing process on the crude product.

03 High technical requirements:

PEEK has good processing performance, but because the melting point of PEEK is as high as 343℃, and the adhesive property of PEEK is relatively strong, the material, structure and temperature control of the molding equipment are relatively high.

04 高い製品要件とさまざまな処理手順:

PEEK 材料の価格が高いため、顧客は最終製品に対して比較的高い要件を持っており、外観品質、公差、表面仕上げなどを厳密に管理する必要があります。一部の製品は複雑な構造をしており、その結果、より多くの処理手順とより多くの人員が関与し、結果としてコストが増加します。

05 製品の小ロット、非標準仕様:

PEEK はその優れた総合性能により、幅広い産業で使用できますが、それらのほとんどは機器の特別な機会に使用されるため、寸法、構造特性、仕様およびモデルが異なります。現在、PEEKを使用した製品は1500以上にのぼります。

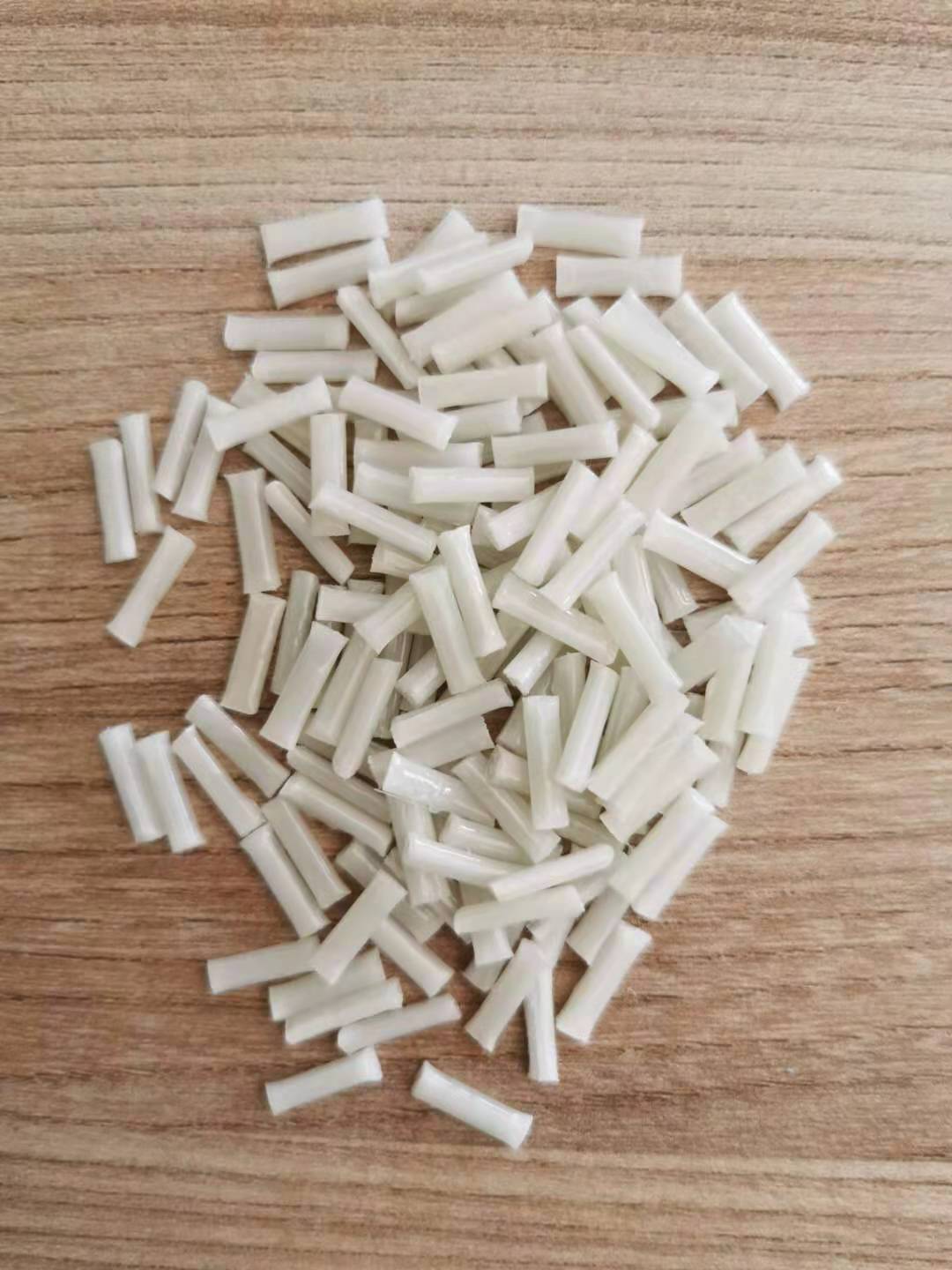

私たちに関しては

厦門 LFT 複合プラスチック有限公司は、LFT&LFRT を専門とするブランド企業です。ロンググラスファイバーシリーズ(LGF)&ロングカーボンファイバーシリーズ(LCF)。同社の熱可塑性 LFT は、LFT-G 射出成形および押出成形に使用でき、LFT-D 成形にも使用できます。お客様のご要望に応じて、長さ5〜25mmで製造できます。 同社の長繊維連続浸透強化熱可塑性樹脂は、ISO9001 & 16949 システム認証に合格し、製品は多くの国内商標と特許を取得しています。