長炭素繊維強化ポリアミドナイロンpa12 溶液含浸法により調製した。 長炭素繊維強化pa12 自動車部品、エレクトロニクス、包装業界ではより重要です。 pa6&と比較できます。 66長炭素繊維の改質

-

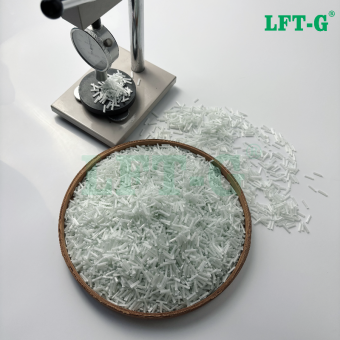

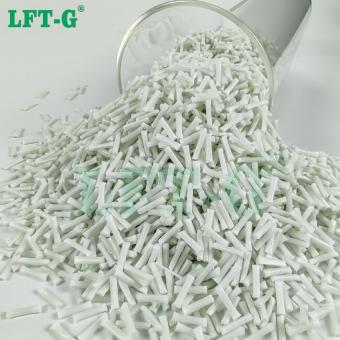

LFT-G 高品質ナイロン PA12 充填 LGF 自動車部品自社工場PA12素材 PA12 はナイロン 12 であり、ポリ ドデカラクタム、ポリ ラウロラクタムとしても知られ、長炭素鎖ナイロンです。 ナイロン 12 には非極性メチレン基が多数存在しており、これによりナイロン 12 分子鎖の柔軟性が高まります。ナイロン12のアミド基は極性があり、凝集エネルギーが非常に大きく、分子間で水素結合を形成できるため、分子配列がより規則的になります。したがって、ナイロン12は結晶性が高く、強度も高い。ナイロン12(PA12) 低吸水性、良好な耐低温性、良好な気密性、耐アルカリ性、耐グリース性に優れ、アルコール、無機希酸、芳香族に対する耐性は中程度で、機械的特性、電気的特性も良好であり、自己消火性のある素材。 PA12充填材 長炭素繊維コンパウンドもっと見る

-

アモイ LFT ポリアミド 12 充填長炭素繊維複合軽量サンプルが入手可能PA12情報 長炭素鎖ナイロンとは、ナイロン分子の主鎖繰り返し単位にアミド基を持ち、2つのアミド基間のメチレン基の長さが10以上のナイロンです。ナイロン11、ナイロン12も含めて長炭素鎖ナイロンと呼びます。 PA12 はナイロン 12で あり、ポリ(ドデカラクタム)およびポリ(ラウロラクタム)としても知られ、長炭素鎖ナイロンの一種です。重合の基本原料は、半結晶性または結晶性の熱可塑性材料であるブタジエンです。ナイロン 12 は最も広く使用されている長炭素鎖ナイロンで、吸水性が低いことに加えてナイロンの一般的な特性をほとんど備えており、高い寸法安定性、高温耐性、耐食性、良好な靭性、加工の容易さなどの利点を備えています。 。別の長い炭素鎖ナイロン材料である PA11 と比較して、PA12 の原料ブタジエンは PA11 の原料ヒマシ油の価格のわずか 3 分の 1 であり、PA11 の代わりにほとんどのシナリオで使用でき、自動車などの多くの分野で幅広い用途があります。燃料ホース、エアブレーキホース、海底ケーブル、3D プリントなど。 長鎖ナイロンの中で、PA12は他のナイロン素材と比較して大きな利点があり、その利点は、吸水性が最も低く、密度が最も低く、融点が低く、耐衝撃性、耐摩擦性、耐低温性、耐燃料性、良好な寸法安定性、良好な耐衝撃性です。 PA12は、PA6、PA66とポリオレフィン(PE、PP)の特性を同時に備えており、軽量かつ物理的および化学的特性の組み合わせを達成し、性能を備えています。化学的特性。 PA12-LCF 母材をコンクリートに例えると、繊維は鉄筋のようなもので、両者を混ぜることはコンクリートに鉄筋を加えるようなものです。コンクリートだけでは鋳物は外力により簡単に割れてしまいますが、高強度の鉄筋を加えてコンクリートが十分に包み込むと一体化します。物体が外力を受けたとき、鉄筋はほとんどの外力に耐えることができるため、全体の構造強度が非常に高くなります。 炭素繊維は多くの優れた特性、炭素繊維の高い軸強度と弾性率、低密度、高い比性能、クリープなし、非酸化環境での超高温耐性、優れた耐疲労性、比熱と非炭素間の電気伝導率を備えています。金属と金属、小さな熱膨張係数と異方性、良好な耐食性、良好なX線透過率。優れた電気伝導性と熱伝導性、優れた電磁シールドなど。従来のガラス繊維と比較して、カーボンファイバーは3倍以上のヤング率を持っています。ケブラー繊維と比較して約2倍のヤング率を持ち、有機溶剤や酸、アルカリに不溶で膨潤し、耐食性に優れています。 ナイロン自体はエンジニアリングプラスチックとして優れた性能を持っていますが、吸湿性があり、製品の寸法安定性に劣ります。強度や硬度も金属とは程遠いです。これらの欠点を克服するために、70 年代以前にはすでに開発が行われていました。人々はその性能を向上させるために、カーボンファイバーや他の種類のファイバーを補強に使用してきました。炭素繊維強化ナイロン材料は、近年急速に発展しています。ナイロンと炭素繊維はエンジニアリングプラスチック材料の分野で優れた性能を持っているため、その複合材料合成は、非強化ナイロンよりもはるかに高い強度と剛性などの2つの優位性を反映しています。 、高温クリープが小さく、熱安定性が大幅に向上し、寸法精度、耐摩耗性が良好です。ダンピングに優れ、ガラス繊維強化と比較して優れた性能を発揮します。したがって、炭素繊維強化ナイロン (CF/PA) 複合材料は近年急速に発展しています。 参考用のデータシート ナイロン 12 は、吸水性が低く、優れた耐低温性、良好な気密性、優れた耐アルカリ性および耐グリース性、アルコール、無機希酸および芳香族化合物に対する中程度の耐性、良好な機械的および電気的特性を備え、自己消火性の材料です。 応用 自動車、スポーツ部品、太陽エネルギー、高級玩具などの産業に適しています。 その他気になる商品 PP-LCF PA6-LCF PA66-LCF

- ナイロン複合ペレット ポリマー顆粒

- ナイロンポリマーLCFメーカー

- 変性素材 ナイロン PA12

- 押出レベルナイロン変性

- pa lcf30プロデューサー混乱生産良い価格

- 炭素繊維強化 PA12 ペレット

タグ :

-

アモイ LFT ポリアミド 12 ロングカーボンファイバー複合ナイロンペレットポリマーLFT PA12 長炭素繊維複合材料のデータシートと技術ガイダンス

- 長炭素繊維複合高強度

- LFT PA12 自動車部品用長炭素繊維

- ナイロン12ペレット ポリマーエンジニアリングプラスチック

- PA12 金属の代わりに顆粒熱可塑性樹脂

- Pa12 ペレット ポリアミド軽量

- PA12長炭素繊維複合材

タグ :

-

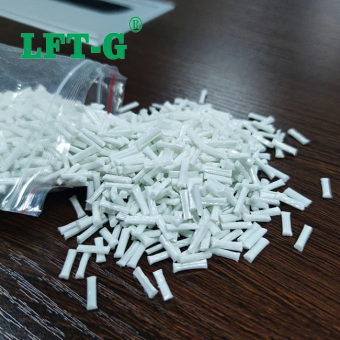

LFT-G ポリアミド 12 充填ロングカーボンファイバープラスチックの高性能オリジナルカラーポリアミド12素材 一般にナイロンとして知られるポリアミド (PA) は、軽量で低コストの製品に対する下流産業の要件を満たすために、金属に代わるエンジニアリング プラスチックとして使用される多様なポリマーのグループです。 ポリアミド系の材質は、耐高温性、電気抵抗性に優れています。結晶構造により、優れた耐薬品性も示します。非常に優れた機械的特性とバリア特性を備えています。さらに、これらの材料は非常に難燃性です。ポリアミドは、真に商用化された最初の合成繊維でした。 炭素繊維(ステープルまたはロング)で強化すると、その剛性は金属の剛性と匹敵する可能性があるため、金属代替プロジェクトではポリアミドがよく検討されます。ポリアミドは、自動車、輸送、エレクトロニクス、電気、消費財の市場で広く使用されています。 PA12の主な特性: 優れた耐薬品性 低温耐衝撃性 耐老化性 高温耐性 耐熱温度(HDT、ピーク温度…)に優れていなくても、耐久性が優れているため、耐温度(HDT、ピーク温度…)に優れていなくても、長期間にわたって安定した性能を発揮 します。幅広い条件(温度、圧力、化学薬品など)で使用できる PA12 は、長期安定性が必要な状況に特に適しています。 応用 その他の応用分野については、技術的なアドバイスについてお問い合わせください。 詳細 番号 色 長さ サンプル パッケージ MOQ 積荷港 納期 PA12-NA-LCF ナチュラルカラー/カスタマイズされた 6-25mm 利用可能 20kg/袋 20kg 厦門港 発送後7-45日 プロデュースプロセスが歌う テスト さらに詳しい資料についてはお問い合わせください

- PA12 LCF パレット ブラック

- 電気アクセサリ用長炭素繊維強化ポリアミド 12

- 自動車部品材料 PA12

- 低反り電子機器

- 繊維入り熱可塑性樹脂 PA12

- ナイロン12複合ペレット ポリマー顆粒

タグ :

-

アモイ LFT ポリアミド 12 ロングカーボンファイバー複合材料軽量高靭性PA12情報 長炭素鎖ナイロンとは、ナイロン分子の主鎖繰り返し単位にアミド基を持ち、2つのアミド基間のメチレン基の長さが10以上のナイロンです。ナイロン11、ナイロン12も含めて長炭素鎖ナイロンと呼びます。 PA12 はナイロン 12 であり、ポリ(ドデカラクタム)およびポリ(ラウロラクタム)としても知られ、長炭素鎖ナイロンの一種です。重合の基本原料は、半結晶性または結晶性の熱可塑性材料であるブタジエンです。ナイロン 12 は最も広く使用されている長炭素鎖ナイロンで、吸水性が低いことに加えてナイロンの一般的な特性をほとんど備えており、高い寸法安定性、高温耐性、耐食性、良好な靭性、加工の容易さなどの利点を備えています。 。別の長い炭素鎖ナイロン材料である PA11 と比較して、PA12 の原料ブタジエンは PA11 の原料ヒマシ油の価格のわずか 3 分の 1 であり、PA11 の代わりにほとんどのシナリオで使用でき、自動車などの多くの分野で幅広い用途があります。燃料ホース、エアブレーキホース、海底ケーブル、3D プリントなど。 長鎖ナイロンの中で、PA12は他のナイロン素材と比較して大きな利点があり、その利点は、吸水性が最も低く、密度が最も低く、融点が低く、耐衝撃性、耐摩擦性、耐低温性、耐燃料性、良好な寸法安定性、良好な耐衝撃性です。 PA12は、PA6、PA66とポリオレフィン(PE、PP)の特性を同時に備えており、軽量かつ物理的および化学的特性の組み合わせを達成し、性能を備えています。化学的特性。 PA12-LCF 母材をコンクリートに例えると、繊維は鉄筋のようなもので、両者を混ぜることはコンクリートに鉄筋を加えるようなものです。コンクリートだけでは鋳物は外力により簡単に割れてしまいますが、高強度の鉄筋を加えてコンクリートが十分に包み込むと一体化します。物体が外力を受けたとき、鉄筋はほとんどの外力に耐えることができるため、全体の構造強度が非常に高くなります。 炭素繊維は、多くの優れた特性、炭素繊維の高い軸強度と弾性率、低密度、高い比性能、クリープなし、非酸化環境での超高温耐性、優れた耐疲労性、比熱と非炭素間の電気伝導率を備えています。金属と金属、小さな熱膨張係数と異方性、良好な耐食性、良好なX線透過率。優れた電気伝導性と熱伝導性、優れた電磁シールドなど。従来のガラス繊維と比較して、カーボンファイバーは3倍以上のヤング率を持っています。ケブラー繊維と比較して約2倍のヤング率を持ち、有機溶剤や酸、アルカリに不溶で膨潤し、耐食性に優れています。 ナイロン自体は優れた性能を有するエンジニアリングプラスチックですが、吸湿性があり、製品の寸法安定性に劣ります。強度や硬度も金属とは程遠いです。これらの欠点を克服するために、70 年代以前にはすでに開発が行われていました。人々はその性能を向上させるために、カーボンファイバーや他の種類のファイバーを補強に使用してきました。炭素繊維強化ナイロン材料は、近年急速に発展しています。ナイロンと炭素繊維はエンジニアリングプラスチック材料の分野で優れた性能を持っているため、その複合材料合成は、非強化ナイロンよりもはるかに高い強度と剛性などの2つの優位性を反映しています。 、高温クリープが小さく、熱安定性が大幅に向上し、寸法精度、耐摩耗性が良好です。ダンピングに優れ、ガラス繊維強化と比較して優れた性能を発揮します。したがって、炭素繊維強化ナイロン (CF/PA) 複合材料は近年急速に発展しています。 参考用のデータシート ナイロン 12 は、吸水性が低く、優れた耐低温性、良好な気密性、優れた耐アルカリ性および耐グリース性、アルコール、無機希酸および芳香族化合物に対する中程度の耐性、優れた機械的および電気的特性を備え、自己消火性の材料です。 応用 自動車、スポーツ部品、太陽エネルギー、高級玩具などの産業に適しています。 その他気になる商品 PP-LCF PA6-LCF PA66-LCFもっと見る

-

LFT-G ポリアミド 12 自動車部品用長炭素繊維強化複合ナイロン長い炭素繊維 炭素繊維は多くの優れた特性を持ち、高い軸強度と弾性率、低密度、高い比性能、クリープなし、非酸化環境での超高温耐性、優れた耐疲労性、非金属と金属間の比熱と電気伝導率、小さい熱膨張係数と異方性、良好な耐食性、良好なX線透過率。優れた電気伝導性と熱伝導性、優れた電磁シールドなど。従来のガラス繊維と比較して、カーボンファイバーは3倍以上のヤング率を持っています。ケブラー繊維と比較して約2倍のヤング率を持ち、有機溶剤や酸、アルカリに不溶で膨潤し、耐食性に優れています。 しかし、炭素繊維の価格を下げる方法はあるのでしょうか? それは、比較的安価なナイロン材料と混合して、優れた性能を備えた複合材料を形成し、要件を満たすことです。その場合、カーボンファイバーナイロンが複合材料に確実に採用されることは間違いありません。 ナイロン自体は優れた性能を有するエンジニアリングプラスチックですが、吸湿性があり、製品の寸法安定性に劣ります。強度や硬度も金属とは程遠いです。これらの欠点を克服するために、70 年代以前にはすでに開発が行われていました。人々はその性能を向上させるために、カーボンファイバーや他の種類のファイバーを補強に使用してきました。炭素繊維強化ナイロン材料は、近年急速に発展しています。ナイロンと炭素繊維はエンジニアリングプラスチック材料の分野で優れた性能を持っているため、その複合材料合成は、非強化ナイロンよりもはるかに高い強度と剛性などの2つの優位性を反映しています。 、高温クリープが小さく、熱安定性が大幅に向上し、寸法精度、耐摩耗性が良好です。ダンピングに優れ、ガラス繊維強化と比較して優れた性能を発揮します。そのため、炭素繊維強化ナイロン(CF/PA)複合材は近年急速に発展しています。SLS テクノロジーを使用した 3D プリンティングは、炭素繊維強化ナイロンを実現するのに最適な技術手段です。 参考のためのTDS 応用 当社 アモイ LFT 複合プラスチック有限公司は、LFT&LFRT に焦点を当てたブランド企業です。長ガラス繊維シリーズ (LGF) および長炭素繊維シリーズ (LCF)。同社の熱可塑性 LFT は、LFT-G 射出成形および押出成形に使用できるほか、LFT-D 成形にも使用できます。お客様のご要望に応じて長さ5~25mmまで製作可能です。同社の連続浸透強化熱可塑性プラスチックは ISO9001&16949 システム認証に合格しており、製品は多くの国内商標と特許を取得しています。もっと見る

-

-

アモイ LFT ポリアミド 12 充填長炭素繊維化合物自動車部品向けの高い耐衝撃性長い炭素繊維 炭素繊維は多くの優れた特性を持ち、高い軸強度と弾性率、低密度、高い比性能、クリープなし、非酸化環境での超高温耐性、優れた耐疲労性、非金属と金属間の比熱と電気伝導率、小さい熱膨張係数と異方性、良好な耐食性、良好なX線透過率。優れた電気伝導性と熱伝導性、優れた電磁シールドなど。従来のガラス繊維と比較して、カーボンファイバーは3倍以上のヤング率を持っています。ケブラー繊維と比較して約2倍のヤング率を持ち、有機溶剤や酸、アルカリに不溶で膨潤し、耐食性に優れています。 しかし、炭素繊維の価格を下げる方法はあるのでしょうか? それは、比較的安価なナイロン材料と混合して、優れた性能を備えた複合材料を形成し、要件を満たすことです。その場合、カーボンファイバーナイロンが複合材料に確実に採用されることは間違いありません。 ナイロン自体は優れた性能を有するエンジニアリングプラスチックですが、吸湿性があり、製品の寸法安定性に劣ります。強度や硬度も金属とは程遠いです。これらの欠点を克服するために、70 年代以前にはすでに開発が行われていました。人々はその性能を向上させるために、カーボンファイバーや他の種類のファイバーを補強に使用してきました。炭素繊維強化ナイロン材料は、近年急速に発展しています。ナイロンと炭素繊維はエンジニアリングプラスチック材料の分野で優れた性能を持っているため、その複合材料合成は、非強化ナイロンよりもはるかに高い強度と剛性などの2つの優位性を反映しています。 、高温クリープが小さく、熱安定性が大幅に向上し、寸法精度、耐摩耗性が良好です。ダンピングに優れ、ガラス繊維強化と比較して優れた性能を発揮します。そのため、炭素繊維強化ナイロン(CF/PA)複合材は近年急速に発展しています。SLS テクノロジーを使用した 3D プリンティングは、炭素繊維強化ナイロンを実現するのに最適な技術手段です。 参考のためのTDS 応用 生産工程 会社概要 アモイ LFT 複合プラスチック有限公司は、LFT&LFRT に焦点を当てたブランド企業です。長ガラス繊維シリーズ (LGF) および長炭素繊維シリーズ (LCF)。同社の熱可塑性 LFT は、LFT-G 射出成形および押出成形に使用できるほか、LFT-D 成形にも使用できます。お客様のご要望に応じて長さ5~25mmまで製作可能です。同社の連続浸透強化熱可塑性プラスチックは ISO9001&16949 システム認証に合格しており、製品は多くの国内商標と特許を取得しています。もっと見る

-

アモイ LFT ポリアミド 12 と長炭素繊維複合軽量サンプルが利用可能PA12情報 長炭素鎖ナイロンとは、ナイロン分子の主鎖繰り返し単位にアミド基を持ち、2つのアミド基間のメチレン基の長さが10以上のナイロンです。ナイロン11、ナイロン12も含めて長炭素鎖ナイロンと呼びます。 PA12 はナイロン 12 であり、ポリ(ドデカラクタム)およびポリ(ラウロラクタム)としても知られ、長炭素鎖ナイロンの一種です。重合の基本原料は、半結晶性または結晶性の熱可塑性材料であるブタジエンです。ナイロン 12 は最も広く使用されている長炭素鎖ナイロンで、吸水性が低いことに加えてナイロンの一般的な特性をほとんど備えており、高い寸法安定性、高温耐性、耐食性、優れた靭性、加工の容易さなどの利点を備えています。 。別の長い炭素鎖ナイロン材料である PA11 と比較して、PA12 の原料ブタジエンは PA11 の原料ヒマシ油の価格のわずか 3 分の 1 であり、PA11 の代わりにほとんどのシナリオで使用でき、自動車などの多くの分野で幅広い用途があります。燃料ホース、エアブレーキホース、海底ケーブル、3D プリントなど。 長鎖ナイロンの中で、PA12は他のナイロン素材と比較して大きな利点があり、その利点は、吸水性が最も低く、密度が最も低く、融点が低く、耐衝撃性、摩擦耐性、耐低温性、耐燃料性、良好な寸法安定性、良好な耐衝撃性です。 PA12は、PA6、PA66とポリオレフィン(PE、PP)の特性を同時に兼ね備えており、軽量かつ物理的および化学的特性の組み合わせを達成し、性能を備えています。化学的特性。 PA12-LCF 母材をコンクリートに例えると、繊維は鉄筋のようなもので、両者を混ぜることはコンクリートに鉄筋を加えるようなものです。コンクリートだけでは鋳物は外力により簡単に割れてしまいますが、高強度の鉄筋を加えてコンクリートが十分に包み込むと一体化します。物体が外力を受けたとき、鉄筋はほとんどの外力に耐えることができるため、全体の構造強度が非常に高くなります。 炭素繊維は、多くの優れた特性、炭素繊維の高い軸強度と弾性率、低密度、高い比性能、クリープなし、非酸化環境での超高温耐性、優れた耐疲労性、比熱と非炭素間の電気伝導率を備えています。金属と金属、小さな熱膨張係数と異方性、良好な耐食性、良好なX線透過率。優れた電気伝導性と熱伝導性、優れた電磁シールドなど。従来のガラス繊維と比較して、カーボンファイバーは3倍以上のヤング率を持っています。ケブラー繊維と比較して約2倍のヤング率を持ち、有機溶剤や酸、アルカリに不溶で膨潤し、耐食性に優れています。 ナイロン自体は優れた性能を有するエンジニアリングプラスチックですが、吸湿性があり、製品の寸法安定性に劣ります。強度や硬度も金属とは程遠いです。これらの欠点を克服するために、70 年代以前にはすでに開発が行われていました。人々はその性能を向上させるために、カーボンファイバーや他の種類のファイバーを補強に使用してきました。炭素繊維強化ナイロン材料は、近年急速に発展しています。ナイロンと炭素繊維はエンジニアリングプラスチック材料の分野で優れた性能を持っているため、その複合材料合成は、非強化ナイロンよりもはるかに高い強度と剛性などの2つの優位性を反映しています。 、高温クリープが小さく、熱安定性が大幅に向上し、寸法精度、耐摩耗性が良好です。ダンピングに優れ、ガラス繊維強化と比較して優れた性能を発揮します。したがって、炭素繊維強化ナイロン (CF/PA) 複合材料は近年急速に発展しています。 参考用のデータシート ナイロン 12 は、吸水性が低く、優れた耐低温性、良好な気密性、優れた耐アルカリ性および耐グリース性、アルコール、無機希酸および芳香族化合物に対する中程度の耐性、優れた機械的および電気的特性を備え、自己消火性の材料です。 応用 自動車、スポーツ部品、太陽エネルギー、高級玩具などの産業に適しています。 その他気になる商品 PP-LCF PA6-LCF PA66-LCF &nbもっと見る

-

LFT-G ポリアミド 12 ロングカーボンファイバー充填変性ナイロン 12 高い耐衝撃性と靭性長い炭素繊維 炭素繊維は、多くの優れた特性、高い軸強度と弾性率、低密度、高い比性能、クリープなし、非酸化環境での超高温耐性、優れた耐疲労性、非金属と金属間の比熱と電気伝導率、小さい熱膨張係数と異方性、良好な耐食性、良好なX線透過率。優れた電気伝導性と熱伝導性、優れた電磁シールドなど。従来のガラス繊維と比較して、カーボンファイバーは3倍以上のヤング率を持っています。ケブラー繊維と比較して約2倍のヤング率を持ち、有機溶剤や酸、アルカリに不溶で膨潤し、耐食性に優れています。 しかし、炭素繊維の価格を下げる方法はあるのでしょうか? それは、比較的安価なナイロン材料と混合して、優れた性能を備えた複合材料を形成し、要件を満たすことです。その場合、カーボンファイバーナイロンが複合材料に確実に採用されることは間違いありません。 ナイロン自体はエンジニアリングプラスチックとして優れた性能を持っていますが、吸湿性があり、製品の寸法安定性に劣ります。強度や硬度も金属とは程遠いです。これらの欠点を克服するために、70 年代以前にはすでに開発が行われていました。人々はその性能を向上させるために、カーボンファイバーや他の種類のファイバーを補強に使用してきました。炭素繊維強化ナイロン材料は、近年急速に発展しています。ナイロンと炭素繊維はエンジニアリングプラスチック材料の分野で優れた性能を持っているため、その複合材料合成は、非強化ナイロンよりもはるかに高い強度と剛性などの2つの優位性を反映しています。 、高温クリープが小さく、熱安定性が大幅に向上し、寸法精度、耐摩耗性が良好です。優れた制振性、ガラス繊維強化と比較して、より優れた性能を発揮します。そのため、炭素繊維強化ナイロン(CF/PA)複合材は近年急速に発展しています。SLS テクノロジーを使用した 3D プリンティングは、炭素繊維強化ナイロンを実現するのに最適な技術手段です。 参考のためのTDS 応用 当社 アモイ LFT 複合プラスチック有限公司は、LFT&LFRT に焦点を当てたブランド企業です。長ガラス繊維シリーズ (LGF) および長炭素繊維シリーズ (LCF)。同社の熱可塑性 LFT は、LFT-G 射出成形および押出成形に使用できるほか、LFT-D 成形にも使用できます。お客様のご要望に応じて長さ5~25mmまで製作可能です。同社の連続浸透強化熱可塑性プラスチックは ISO9001&16949 システム認証に合格しており、製品は多くの国内商標と特許を取得しています。もっと見る

-

Lft-g PA12原料充填ロングカーボンファイバー新プラスチック高性能オリジナルカラーサンプル無料ポリアミド12素材 一般にナイロンとして知られるポリアミド (PA) は、軽量で低コストの製品に対する下流産業の要件を満たすために、金属に代わるエンジニアリング プラスチックとして使用される多様なポリマーのグループです。 ポリアミド系の材質は、耐高温性、電気抵抗性に優れています。結晶構造により、優れた耐薬品性も示します。非常に優れた機械的特性とバリア特性を備えています。さらに、これらの材料は非常に難燃性です。ポリアミドは、真に商用化された最初の合成繊維でした。 炭素繊維(ステープルまたはロング)で強化すると、その剛性は金属の剛性と匹敵する可能性があるため、金属代替プロジェクトではポリアミドがよく検討されます。ポリアミドは、自動車、輸送、エレクトロニクス、電気、消費財の市場で広く使用されています。 PA12の主な特性: 優れた耐薬品性 低温耐衝撃性 耐老化性 高温耐性 耐熱温度(HDT、ピーク温度…)に優れていなくても、耐久性が優れているため、耐温度(HDT、ピーク温度…)に優れていなくても、長期間にわたって安定した性能を発揮します 。幅広い条件(温度、圧力、化学薬品など)で使用できる PA12 は、長期安定性が必要な状況に特に適しています。 応用 その他の応用分野については、技術的なアドバイスについてお問い合わせください。 詳細 番号 色 長さ サンプル パッケージ MOQ 積荷港 納期 PA12-NA-LCF ナチュラルカラー/カスタマイズされた 6-25mm 利用可能 20kg/袋 20kg 厦門港 発送後7-45日 プロデュースプロセスが歌う テスト さらに詳しい資料についてはお問い合わせくださいもっと見る

-

LFT-G ナイロン 12 フィラー長炭素繊維 LCF 20%-60% 配合高強度軽量 6-25mmポリアミド 12 PA12、ナイロン 12 は、ポリドデカラクタムおよびポリラクタムとしても知られ、長炭素鎖ナイロンです。 ナイロン 12 には非極性メチレン基があり、その数が多いため、ナイロン 12 分子鎖の柔軟性が大きくなります。ナイロン12のアミド基は極性があり、凝集エネルギーが大きく、分子間に水素結合を形成することができるため、分子の配列がより規則的になります。したがって、ナイロン12は結晶性が高く、強度も高い。ナイロン 12 (PA12) は、低吸水性、良好な耐低温性、良好な気密性、優れた耐アルカリ性、グリース性能、アルコールおよび無機希酸および芳香族化合物に対する中程度の耐性、良好な機械的特性および電気的特性を備え、自己消火性を備えています。材料。 1) 密度 ナイロン12の相対密度は1.01~1.03とエンジニアリングプラスチックの中で最も小さく、自動車の軽量化、燃費の低減に一定の効果があります。単位体積で比較すると、価格、性能ともにナイロン12が有利です。 2) 融点 ナイロン 12 の融点は 172 ~ 178℃で、ナイロン 11 よりわずかに低く、自動車の燃料およびエアブレーキパイプの使用温度要件を十分に満たすことができます。 3)吸水性 ご存知のとおり、ナイロン製品の最大の欠点は吸水性が高く、寸法安定性を確保することが難しいことです。しかし、ナイロン12はメチレン分子の増加により親水基の影響が大幅に軽減されるため、ナイロン製品の中で最も吸水率が低く、吸水による製品の性能やサイズの変化が少なくなります。 、このためナイロン 12 には大きな利点があります。吸水後の引張強さの低下はナイロン 12 ではほとんどありませんが、ナイロン 66 やナイロン 6 では大きく変化します。 4) 衝撃強度 衝撃強度は重要な技術指標であり、空気にさらされることが多いナイロン 12 チューブでは特に重要です。ナイロン12は、標準試験によると-20℃および-40℃で破断現象がなく、使用要件を完全に満たしています。ナイロン12は耐衝撃性に非常に優れています。 5)低温性能 ナイロン12の最低脆化温度は-70℃であり、低温耐性のある部品に広く使用できます。 6) 柔軟性 可塑剤がナイロン 12 の物理的特性に与える影響は、樹脂の弾性率に集中します。ナイロン 12 樹脂には 3 つの基本的なタイプがあり、それらの主な違いは可塑剤の含有量の違いと柔軟性の形成の違いです。可塑剤抽出成分の含有量が増加すると、樹脂の弾性率は低下します。 7)低摩耗・低摩擦特性 ナイロン12は、低摩耗・低摩擦特性と自己潤滑性に優れており、ナイロン12製品の摩擦音が非常に低くなります。 8)耐燃料性 自動車では、酸素添加燃料、高芳香族燃料、アルコール混合燃料が現在使用されているため、多くのホース材料の分解が発生します。この環境での使用については、ナイロン 11、ナイロン 12、およびフルオロカーボン エラストマーのみがテストされています。自動車燃料の作用下では、すべてのナイロンが溶解し、特にメタノール含有ガソリンでは寸法変化が生じます。ナイロン 6 などの大量のアミド基を含むナイロンは、ナイロン 12 などの少量のアミド基を含むナイロンよりもはるかに多く溶解します。 %。メタノールを 15% 含む燃料はナイロンに大きな影響を与えることがわかります。 9) 塩化亜鉛溶液に対する耐性 塩化亜鉛は車の下の環境に現れます。特定の温度と湿度の下では、道路上の塩が亜鉛メッキ鋼板または亜鉛含有プライマーと反応して、少量の塩化亜鉛が生成されます。塩化亜鉛は腐食性が非常に高いですが、ナイロン 12 は塩化亜鉛溶液に対して非常に耐性があります。オゾン劣化、紫外線暴露、温度条件などにより、部品にさまざまな程度の損傷が生じ、耐用年数が短くなる可能性があります。ナイロン 12 には、オゾンの影響を受けやすい + 2 3 2 + 不飽和二重結合が含まれていないため、オゾン老化の影響を受けません。 また、ナイロン12は結晶性が高く、融解温度が高いため耐熱性がより安定しており、熱安定剤の添加により耐熱性が飛躍的に向上します。太陽光にさらされると、そのエネルギーにより有機材料の化学結合が切断され�

- ポリアミド 12 エンジニアリング プラスチック lcf

- 強化ナイロン 12 CFRP ブラック

- 射出成形 PA12 炭素繊維

- LFT-G 新素材 pa12 cf 代わりに金属

- グリーンプラスチックリサイクルPA12 LCF

タグ :

Eメール

Eメール 日本語

日本語 English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 한국의

한국의 中文

中文