-

-

PA66ペレット ガラス繊維ナイロン6,6 は、ナイロン6の結晶性の高いバージョンです。ポリアミド66またはPA66とも呼ばれます 機械特性の向上 より整然とした分子構造により、機械加工用のナイロン66は 耐熱性の向上 および 吸水率の低下 標準ナイロン6と比較した場合。

- ナイロン66 PA66

タグ :

-

PA12 ペレット ガラス繊維Pa12 gf20 は、ポリアミド12(PA12)を20%のガラス繊維で強化したエンジニアリングプラスチックの一種です。純粋なナイロン12に比べて多くの利点を持つ高性能素材です。 より高い強度、剛性、耐熱性、耐薬品性、および電気特性 Pa12 gf20は、次のようなさまざまな産業のさまざまな用途に広く使用されています。 自動車、航空宇宙、医療、電気、産業 。

- ナイロン12 PA12

タグ :

-

PBTペレットガラス繊維PBT GF30 は、優れた性能を提供する高性能熱可塑性複合材料です。 機械的強度と耐熱性 この複合材料は、強化することによって作られます ポリブチレンテレフタレート(PBT) 樹脂入り ガラス繊維30% PBT GF30 は、そのユニークな特性と利点により、さまざまな業界で応用されています。もっと見る

-

TPUペレット ガラス繊維TPU プラスチックの正式名称は熱可塑性ポリウレタンプラスチックです。これは熱可塑性プラスチックグループに属し、溶融加工されるプラスチックです。その中でも、TPUプラスチックは、柔軟性、強靭性、優れた引張強度など、ゴムとプラスチックの両方の特性を備えている点で際立っています。TPUの代表的な用途分野には、自動車技術、ケーブル、一部のスポーツ用品などがあります。もっと見る

-

ABSペレット ガラス繊維ABS 射出成形とは、溶融したABS樹脂を高温高圧下で金型に注入するプロセスを指します。ABS樹脂は広く使用されているため、射出成形の用途は多岐にわたります。 自動車、消費財、建設業界 いくつか例を挙げます。もっと見る

-

耐高温PPAガラス繊維ポリマー幅広い用途ポリフタルアミド(PPA) 半結晶性の芳香族ポリアミドです。ポリアミド、または ナイロン 、ファミリー。ナイロン6/6と比較すると、 より強く、より硬く、湿気に敏感ではなく、より高い熱能力を持っています さらに、それは以下のことに対して強い耐性を持っています 化学疲労 そして 機械的クリープ 。もっと見る

-

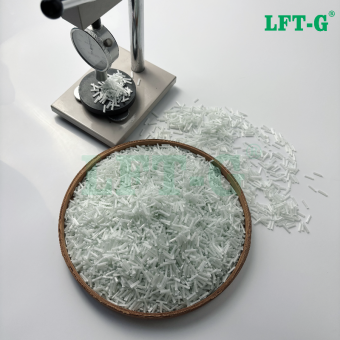

長ガラス繊維入りポリプロピレン強化プラスチックペレット学年: General grade, Heat-resistant grade, UV-resistant grade, Toughen resistant grade Fiber specification: 20%-70%

- 一般グレード改質PP GF30

- 耐熱グレードロングカットPPポリマー

- 家電製品向け耐紫外線グレードPP LFT

- ガラス繊維を充填した耐強靭グレードPP

- 金属の代わりに射出グレードのPPコンパウンド

- 幅広い用途のPP熱可塑性樹脂

タグ :

-

HPP一般グレード充填材 長ガラス繊維 LGF ポリプロピレン改質プラスチック強化材料ポリプロピレン , also known as PP , is a polyolefin or saturated polymer . It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.もっと見る

-

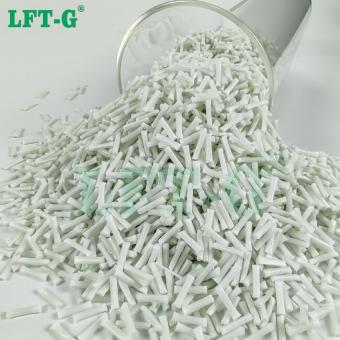

LFT-G PA6 ポリアミド6 ナイロン6 充填長ガラス繊維40 オリジナルカラー 自動車部品用PA6およびPA6-LGF長ガラス繊維強化ナイロン PA6, also known as Nylon 6, is a high-performance polyamide widely used in engineering plastics, fibers, and films. It is a thermoplastic polymer with repeating amide groups (-NH-CO-) in the main chain, offering strong mechanical properties and versatile processing capabilities. What is PA6 Plastic? PA6 is an aliphatic polyamide that provides excellent strength, wear resistance, and chemical resistance to weak acids, alkalis, and certain organic solvents. Its lightweight and processable nature make it widely applied in fibers, engineering plastics, and thin films. However, the polar amide groups in PA6 easily form hydrogen bonds with water molecules, which can result in high moisture absorption, dimensional changes, and reduced impact strength in dry or low-temperature conditions. Advantages of PA6 High mechanical strength and toughness with excellent tensile and compressive properties Outstanding fatigue resistance, maintaining strength after repeated bending High softening point, heat resistant Low friction and wear-resistant surface Corrosion resistance to alkalis, salts, weak acids, oils, and most solvents Self-extinguishing, non-toxic, odorless, and good weather and biological resistance Excellent electrical insulation even in high humidity environments Lightweight, easy to dye, and easy to mold due to low melting viscosity Limitations of PA6 High moisture absorption (up to 3% when saturated) Poor light and thermal stability; prolonged high-temperature exposure may cause discoloration and surface cracking Strict injection molding requirements; trace moisture can affect product quality Dimensional stability is sensitive to thermal expansion and wall thickness variations Not resistant to strong acids or oxidizing agents; unsuitable for acid-resistant applications Why Reinforce PA6 with Long Glass Fiber? To overcome the natural limitations of PA6, long glass fiber (LGF) reinforcement is applied. PA6-LGF composites combine the lightweight, chemical, and heat resistance of PA6 with the mechanical strength and dimensional stability of long glass fibers. LGF reinforcement improves tensile, compressive, and flexural strength, reduces shrinkage, enhances fatigue resistance, and provides improved thermal and chemical stability. This makes PA6-LGF ideal for high-performance structural components. Applications of PA6-LGF PA6 reinforced with 30% long glass fiber (30% LGF) is widely used in: Power tool shells and components Engineering machinery parts Automobile structural and functional components The composite improves mechanical strength, dimensional stability, heat resistance, aging resistance, and fatigue resistance. Its fatigue strength can be up to 2.5x that of unreinforced PA6. Processing and Forming Tips for 30% PA6-LGF Shrinkage is reduced to ~0.3% compared with 1–1.5% for pure PA6. Excessive fiber content may cause surface floating fibers and poor compatibility. 30% LGF is recommended for balanced performance. Recycled material content should be kept below 25% to avoid color and mechanical property degradation. Gradual cooling after molding prevents warping due to fiber orientation during injection molding. Mold design, gate position, and temperature control are critical. Customers & Staffs Certificatesもっと見る

-

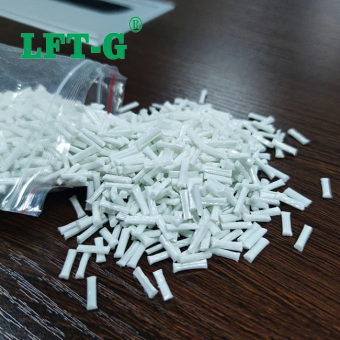

LFT-G改質ナイロン66 PA66充填長ガラス繊維複合電子機器PA66-LGF 長ガラス繊維強化ナイロン PA66, or Nylon 66, is a high-performance polyamide widely used in engineering plastics. It offers excellent mechanical properties including tensile strength, flexural strength, and impact resistance, along with superior thermal and chemical stability. With lightweight, high wear resistance, good electrical insulation, and self-extinguishing properties, PA66 is ideal for automotive, electrical, industrial equipment, and construction applications. Why Reinforce PA66 with Long Glass Fiber? While PA66 is versatile, it has limitations: high water absorption, low compressive strength when wet, poor alkali resistance, and potential deformation at ultra-low temperatures. Long glass fiber (LGF) reinforcement addresses these challenges. Adding LGF significantly improves impact resistance, thermal deformation resistance, mechanical performance, molding processability, and chemical resistance. LGF acts as a robust internal skeleton, enhancing the durability and reliability of PA66 components. PA66-LGF Technical Datasheet *The datasheet is tested by Xiamen LFT and provided for reference only.* Applications of PA66-LGF PA66 reinforced with 30% long glass fiber is ideal for high-performance applications such as: Automotive components and structural parts Power tool housings and mechanical parts Industrial equipment components For specialized applications, please consult our technical team. PA66-LGF Product Details Number Color Length Sample MOQ Port of Loading Delivery Time Payment Terms PA66-NA-LGF30 Original color (customizable) 12mm (customizable) Available 25kg Xiamen Port 7-15 days after shipment Discussed Xiamen LFT Composite Plastic Co., Ltd Xiamen LFT Composite Plastic Co., Ltd. is a leading manufacturer specializing in long fiber reinforced thermoplastics (LFT & LFRT), including Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) series. Our thermoplastic LFT can be applied in LFT-G injection molding, extrusion molding, and LFT-D molding. We provide products according to customer requirements with fiber lengths from 5 to 25mm. Our continuous infiltration reinforced thermoplastics have passed ISO9001 & 16949 certifications and hold numerous national patents and trademarks. Our Services Technical parameters and leading-edge design of LFT & LFRT materials Mold front design recommendations Technical support for injection molding and extrusion molding processes

- 低反り電子機器

- 自己所有PA66ペレット

- 高強度・高靭性強化PA66ペレット

- 最高の長ガラス繊維PA66 LGF30顆粒

- PA66 6ツインスクリューLGFペレット

- 長繊維PA66顆粒の用途

タグ :

-

PLAポリ乳酸化合物長ガラス繊維熱可塑性樹脂エンジニアリング用PLA & LGFPLA – 環境に優しい強化バイオプラスチック PLA (Polylactic Acid) is a non-natural polyester and one of the most promising "green plastics." Known for its biocompatibility, biodegradability, and high mechanical strength, PLA can be completely degraded by microorganisms into CO₂ and water, making it non-toxic and environmentally friendly. PLA offers mechanical properties similar to polypropylene, while providing the gloss, clarity, and processability of polystyrene. With a lower processing temperature than polyolefins, PLA can be molded via injection molding, extrusion, blow molding, spinning, and other general plastic processes. Its applications range from disposable packaging and fibers to nonwovens, and extend to medical, chemical, pharmaceutical, and 3D printing industries. Long Glass Fiber Reinforced PLA (LGFPLA) Glass fiber is an inorganic non-metallic material with excellent insulation, heat resistance, corrosion resistance, and mechanical strength. When used to reinforce PLA, it creates Long Glass Fiber PLA (LGFPLA), a high-performance thermoplastic composite with glass fibers 10–25mm long, forming a 3D structure for superior strength and stability. LGFPLA is available as columnar pellets, typically 12mm (for injection molding) or 25mm (for compression molding) in length, with glass fiber content from 20% to 60%. Colors can be customized to match client requirements. Advantages of LGF vs SGF (Long Fiber vs Short Fiber PLA) Longer fiber length improves mechanical properties and part durability. High specific stiffness and strength, with excellent impact resistance — ideal for automotive parts. Improved creep resistance and dimensional stability for precise molding. Outstanding fatigue resistance and long-term reliability. Stable performance in high temperature and humid environments. Minimal fiber damage during molding due to fiber mobility within the mold. Technical Specifications Product Number Color Length Fiber Specification Package Sample Port of Loading Delivery Time PLA-NA-LGF Natural or customizable 6–25mm 20%–60% 25kg/bag Available Xiamen Port 7–15 days after shipment Lab & Factory Xiamen LFT Composite Plastic Co., Ltd. Xiamen LFT Composite Plastic Co., Ltd. specializes in developing and producing long glass fiber (LGF) and long carbon fiber (LCF) reinforced thermoplastic composites (LFT-G, LFRT, LFT). Our materials are lightweight, high-strength, impact-resistant, and environmentally friendly, offering excellent corrosion and chemical resistance along with superior molding performance. Our products are used across industries including automotive, aerospace, military, electrical, medical, sports equipment, and daily consumer goods, producing components such as gears, rollers, pulleys, pump impellers, fan blades, and more.

- PLA強化プラスチックLGF生産PLA

- LFT-G PLA射出成形用改質材料

- 長ガラス繊維複合材PLA樹脂基本

- 中国製の長繊維PLAペレット30個

- 自己所有PLAポリマーメーカー直販

- PLA純粋ペレットバージングレードLFT

タグ :

Eメール

Eメール 日本語

日本語 English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 한국의

한국의 中文

中文