商品番号。:

PA6-NA-LGF30お支払い:

T/T or L/C (other payment ways also can be di製品の起源:

Xiamen, China色:

Original color (also can be customized)出荷ポート:

Xiamen, ChinaPA6 material

PA6 is one of the most widely used materials in the current field, and PA6 is a very good engineering plastic with balanced and good performance. The raw materials for the manufacture of nylon 6 engineering plastic are extensive and inexpensive, and it is not restricted by the technological monopoly of foreign companies.

However, in order to make good use of this inexpensive and excellent material, we must first understand it. Today, we will start with glass fiber reinforced PA6 engineering plastics, because it is the most important category of PA6 engineering plastics.

Just like any other engineering plastics, PA6 has advantages and disadvantages, such as high water absorption, low temperature impact toughness and dimensional stability is relatively poor. So engineers will use different methods to make PA6 better, which we call modification. At present, the most common method is to blend and modify PA6 with glass fiber (GF).

Today, we will take a look at the mechanical properties of PA6 engineering plastics under the glass fiber GF system for reference and help us select materials.

PA6-LGF

1. Influence of glass fiber content on PA6 engineering plastics

We can find from the application and experiment that the content index is often one of the biggest influencing factors in fiber reinforced composites.

As the glass fiber content increases, the number of glass fibers per unit area of the material will increase, which means that the PA6 matrix between the glass fibers will become thinner. This change determines the impact toughness, tensile strength, bending strength and other mechanical properties of glass fiber reinforced PA6 composites.

In terms of impact performance, the increase of glass fiber content will greatly increase the notch impact strength of PA6. Taking long glass fiber (LGF) filling PA6 as an example, when the filling volume increases to 35%, the notch impact strength will increase from 24.8J/m to 128.5J/m.

But the glass fiber content is not more is better, short glass fiber (SGF) filling volume reached 42%, the impact strength of the material reached the highest 17.4kJ/㎡, but continue to add will let the gap impact strength showed a downward trend.

In terms of bending strength, the increase of the amount of glass fiber will make the bending stress can be transferred between the glass fiber through the resin layer; At the same time, when the glass fiber is extracted from the resin or broken, it will absorb a lot of energy, thus improving the bending strength of the material.

The above theory is verified by experiments. The data show that the bending elastic modulus increases to 4.99GPa when the LGF (long glass fiber) is filled to 35%. When the content of SGF (short glass fiber) is 42%, the bending elastic modulus reaches 10410MPa, which is about 5 times that of pure PA6.

2. Influence of glass fiber retention length on PA6 composites

The fiber length of the glass fiber also has an obvious effect on the mechanical properties of the material. When the length of the glass fiber is less than the critical length (the length of the fiber when the material has the tensile strength of the fiber), the interface binding area of the glass fiber and the resin increases with the increase of the length of the glass fiber. When the composite material is broken, the resistance of the glass fiber from the resin is also greater, so as to improve the ability to withstand the tensile load.

When the length of glass fiber exceeds the critical, the longer glass fiber can absorb more impact energy under impact load. In addition, the end of the glass fiber is the initiation point of crack growth, and the number of long glass fiber ends is relatively less, and the impact strength can be significantly improved.

The experimental results show that the tensile strength of the material increases from 154.8MPa to 164.4MPa when the glass fiber content is kept at 40% and the length of the glass fiber increases from 4mm to 13mm. The bending strength and notched impact strength increased by 24% and 28%, respectively.

Moreover, the research shows that when the original length of the glass fiber is less than 7mm, the material performance increases more obviously. Compared with short glass fiber, long glass fiber reinforced PA6 material has better appearance warping resistance, and can better maintain mechanical properties under high temperature and humidity conditions.

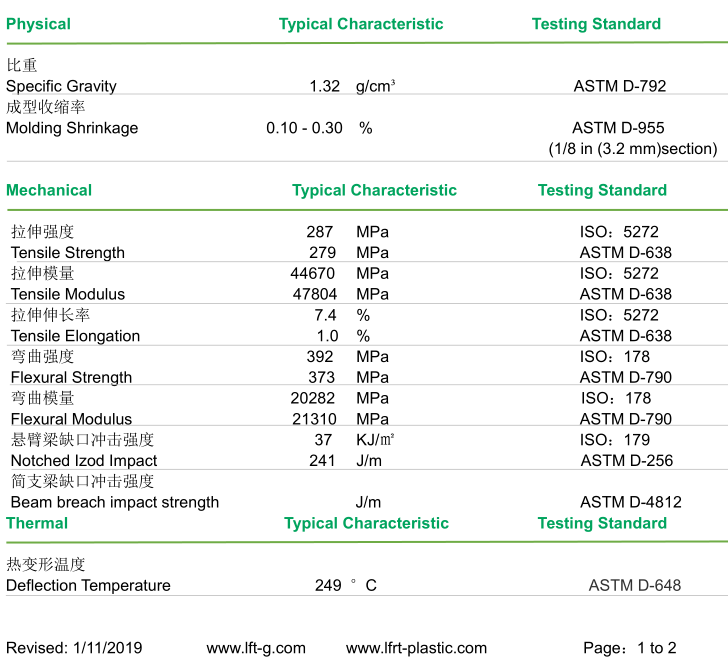

TDS for your reference

PA6 can be made into long glass fiber reinforced material by adding 20%-60% long glass fiber according to the characteristics of the product. PA6 with long glass fiber added has better strength, heat resistance, impact resistance, dimensional stability and warping resistance than without glass fiber added. Following TDS show the data of PA6-LGF30.

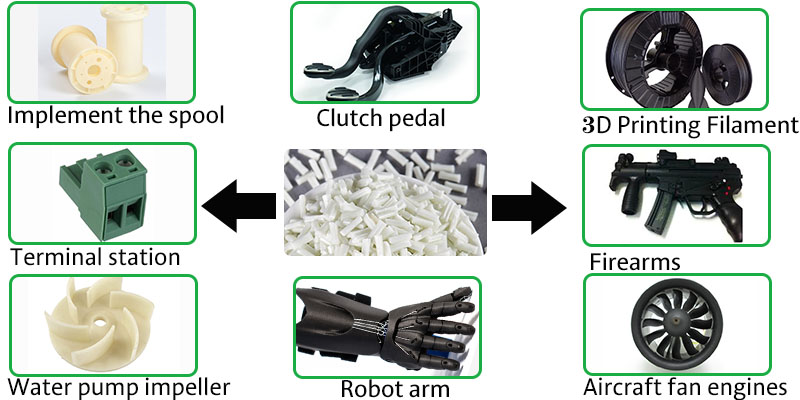

Application

PA6-LGF has the largest proportion of applications in the automotive industry, by electronic and electrical applications, and also involving machinery and engineering parts.

Auto parts

The development demand of miniaturization and lightweight of automobile promotes the application of PA6 in automobile industry. PA6 components have been used in automotive engine, electrical and body systems.

Electronic and electrical

Good flame retardant and corrosion resistance of PA6 makes it suitable for making all kinds of low voltage switchgear, circuit breakers, contactors, connectors and cable protection tubes after glass fiber reinforcement.

Mechanical and engineering parts

The advantages of PA6 such as good impact resistance, wear resistance and self lubrication make it widely used in all kinds of machinery and engineering accessories.

Xiamen LFT company

LFT は、LFT&LFRT に焦点を当てたブランド会社です。長ガラス繊維シリーズ (LGF) および長炭素繊維シリーズ (LCF)。同社の熱可塑性 LFT は、LFT-G 射出成形および押出成形に使用できるほか、LFT-D 成形にも使用できます。お客様のご要望に合わせて製作可能です:長さ5~25mm。同社の長繊維連続浸透強化熱可塑性プラスチックは ISO9001&16949 システム認証に合格しており、製品は多くの国内商標と特許を取得しています。