商品番号。:

PBT-NA-LGFお支払い:

T/T or L/C (other payment ways also can be di製品の起源:

Xiamen, China色:

Original color (also can be customized)出荷ポート:

Xiamen, ChinaPBT-LGF

Polybutanediol terephthalate (PBT) has excellent comprehensive properties, such as high crystallinity, rapid prototyping, weather resistance, low friction coefficient, high thermal deformation temperature, good electrical properties, excellent mechanical properties, fatigue resistance, can be ultrasonic welding.

However, its notched impact strength is low, forming shrinkage rate is large, hydrolysis resistance is poor, easy to be eroded by halogenated hydrocarbons, after glass fiber reinforcement, because of the product longitudinal and horizontal shrinkage is inconsistent easy to warping products.

With its excellent comprehensive performance, PBT is widely used in electronic and electrical appliances, automobile industry, machinery, instruments and household appliances and other fields.

Common problem & Solvement

Glass fiber reinforced PBT material warps easily

Reasons:

Warping is the result of uneven shrinkage of the material. The warping of the product can be caused by the orientation and crystallization of the components in the material, the improper technological conditions used in the injection molding, the wrong shape and position of the gate in the mold design, and the uneven thickness of the wall in the product design. The warping of PBT/GF composites is mainly due to the fact that the orientation of the glass fiber in the flow direction restricts the shrinkage of the resin, and the induced crystallization of PBT around the glass fiber strengthens this effect, making the longitudinal (flow direction) shrinkage of the product less than the transverse (perpendicular to the flow direction). This uneven shrinkage leads to the warping of PBT/GF composites.

Solution:

1. Add minerals and use the shape symmetry of mineral fillers to reduce the anisotropy caused by the glass fiber orientation;

2. Add amorphous materials to reduce the crystallinity of PBT and reduce the uneven shrinkage caused by crystallization, such AS ASA or AS, but they have poor compatibility with PBT, so appropriate compatibilizers need to be added;

3. Adjust injection molding process, such as increasing mold temperature and increasing injection cycle appropriately.

Glass fiber reinforced PBT surface floating fiber problem

Reasons:

The causes of floating fiber are more complex, in short, there are mainly the following aspects

1. The compatibility of PBT and glass fiber is very poor, resulting in the two can not effectively bond together;

2. The viscosity of PBT and glass fiber is very different, resulting in a tendency of separation between the two in the flow process. When the separation effect is greater than the adhesive force, the separation will occur, and the glass fiber will float to the outer layer and leak out;

3. The existence of shear force will not only lead to local viscosity differences, but also destroy the interface layer melt viscosity on the glass fiber surface, the smaller the interface layer is damaged, the smaller the bonding force on the glass fiber. When the viscosity is low to a certain degree, the glass fiber will get rid of the PBT resin matrix and gradually accumulate to the surface and expose.

4. Influence of mold temperature. Due to the low temperature of the mold surface, the glass fiber with light weight and fast condensation is frozen instantaneously. If it is not fully surrounded by melt in time, it will be exposed and form "floating fiber".

Solution:

1) Add compatibilizers, dispersants and lubricants to improve the floating fiber problem. For example, the use of special surface treatment of glass fiber, or adding compatibilizers (such as: SOG, a well-flowing PBT modified compatibilizer) through the "bridge" effect, increase the adhesion of PBT and glass fiber.

2) Optimize the molding process to improve the floating fiber problem. Higher injection molding temperature and mold temperature, larger injection molding pressure and back pressure, faster injection molding speed, lower screw speed, can improve the floating fiber problem to a certain extent.

The glass fiber reinforced PBT injection molding process is easy to produce more mold scale

Reasons:

The formation of mold scale is caused by the high content of small molecules or the poor thermal stability of materials. Compared with other materials, PBT is easy to generate mold scale due to its oligomer and small molecule residue rate usually in the range of 1%-3%. And after the introduction of glass fiber, more obvious. This will lead to the continuous processing process, the need to clean the mold regularly, resulting in low production efficiency.

Solution:

1) Reduce the amount of small molecule additives (such as lubricant, coupling agent, etc.), try to choose polymer additives;

2) PBT の熱安定性を向上させ、加工中の熱劣化によって生成される小分子生成物を削減します。

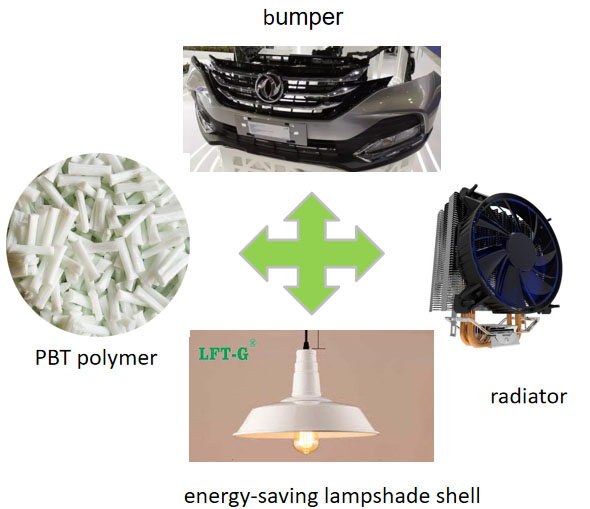

PBT アプリケーション

機械、電子・電気、自動車産業、家電などの分野で広く使用されています。

関連情報

| 色 | 長さ | サンプル | パッケージ | 積荷港 | 発送時間 |

| 自然 | 5mm~12mm | 利用可能 | 25kg/袋 | 厦門港 | 発送後7-15日 |

私たちを追い出してください