-

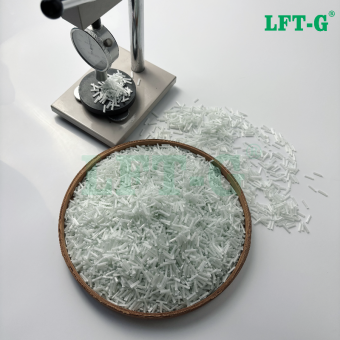

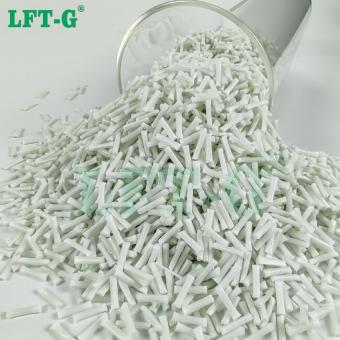

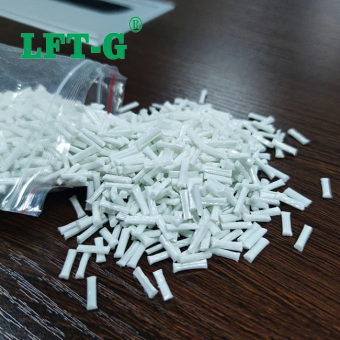

LFT-G ポリアミド6ナイロン6充填長ガラス繊維(自動車部品用オリジナルカラー)の主な利点は ナイロン6 その 硬直 そして 耐摩耗性 さらに、この材料は 優れた衝撃強度 、 耐摩耗性 、 そして 電気絶縁性 ナイロン6は 非常に弾力性がある そして 疲労に強い素材 つまり、張力によって変形した後、元の形状に戻ります。このポリアミドは無毒で、ガラス繊維やカーボン繊維と組み合わせることで性能を向上させることができます。

- ポリアミド6複合材料の特性

- LGF熱可塑性樹脂 良い価格

- 金属プラスチックの代わりに高衝撃PA6

- 射出成形プラスチックGF30フィルター

- PA6充填長ガラス繊維カスタマイズ

- 強化プラスチック軽量複合材

タグ :

-

ナイロン強化ペレット PA6 炭素繊維ナイロン6 は、 射出成形 成形されたナイロン部品は、優れた強度、耐薬品性、耐熱性を備えています。ナイロン6を成形する際には、材料に一定量の ガラス繊維または炭素繊維 (通常は 20%と60% )を採用することで引張強度を高めています。もっと見る

-

LFT-G PA6 ポリアミド6 ナイロン6 充填長ガラス繊維40 オリジナルカラー 自動車部品用PA6およびPA6-LGF長ガラス繊維強化ナイロン PA6, also known as Nylon 6, is a high-performance polyamide widely used in engineering plastics, fibers, and films. It is a thermoplastic polymer with repeating amide groups (-NH-CO-) in the main chain, offering strong mechanical properties and versatile processing capabilities. What is PA6 Plastic? PA6 is an aliphatic polyamide that provides excellent strength, wear resistance, and chemical resistance to weak acids, alkalis, and certain organic solvents. Its lightweight and processable nature make it widely applied in fibers, engineering plastics, and thin films. However, the polar amide groups in PA6 easily form hydrogen bonds with water molecules, which can result in high moisture absorption, dimensional changes, and reduced impact strength in dry or low-temperature conditions. Advantages of PA6 High mechanical strength and toughness with excellent tensile and compressive properties Outstanding fatigue resistance, maintaining strength after repeated bending High softening point, heat resistant Low friction and wear-resistant surface Corrosion resistance to alkalis, salts, weak acids, oils, and most solvents Self-extinguishing, non-toxic, odorless, and good weather and biological resistance Excellent electrical insulation even in high humidity environments Lightweight, easy to dye, and easy to mold due to low melting viscosity Limitations of PA6 High moisture absorption (up to 3% when saturated) Poor light and thermal stability; prolonged high-temperature exposure may cause discoloration and surface cracking Strict injection molding requirements; trace moisture can affect product quality Dimensional stability is sensitive to thermal expansion and wall thickness variations Not resistant to strong acids or oxidizing agents; unsuitable for acid-resistant applications Why Reinforce PA6 with Long Glass Fiber? To overcome the natural limitations of PA6, long glass fiber (LGF) reinforcement is applied. PA6-LGF composites combine the lightweight, chemical, and heat resistance of PA6 with the mechanical strength and dimensional stability of long glass fibers. LGF reinforcement improves tensile, compressive, and flexural strength, reduces shrinkage, enhances fatigue resistance, and provides improved thermal and chemical stability. This makes PA6-LGF ideal for high-performance structural components. Applications of PA6-LGF PA6 reinforced with 30% long glass fiber (30% LGF) is widely used in: Power tool shells and components Engineering machinery parts Automobile structural and functional components The composite improves mechanical strength, dimensional stability, heat resistance, aging resistance, and fatigue resistance. Its fatigue strength can be up to 2.5x that of unreinforced PA6. Processing and Forming Tips for 30% PA6-LGF Shrinkage is reduced to ~0.3% compared with 1–1.5% for pure PA6. Excessive fiber content may cause surface floating fibers and poor compatibility. 30% LGF is recommended for balanced performance. Recycled material content should be kept below 25% to avoid color and mechanical property degradation. Gradual cooling after molding prevents warping due to fiber orientation during injection molding. Mold design, gate position, and temperature control are critical. Customers & Staffs Certificatesもっと見る

-

Eメール

Eメール 日本語

日本語 English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 한국의

한국의 中文

中文