製品グレード:一般グレード

繊維の指定: 30%-60%

製品特徴:難燃性、耐熱性、耐薬品性、低摩擦係数、耐荷重性良好

製品の用途: 航空、機械、電子、化学、自動車、その他のハイテク分野。

製品グレード:一般グレード

繊維の指定: 30%-60%

製品特徴:難燃性、耐熱性、耐薬品性、低摩擦係数、耐荷重性良好

製品の用途: 航空、機械、電子、化学、自動車、その他のハイテク分野。

商品番号。:

PEEK-NA-LCF30お支払い:

T/T or L/C (other payment ways also can be di製品の起源:

Xiamen, China色:

Original color (also can be customized)出荷ポート:

Xiamen, ChinaProduct information

1. PEEK is one of the existing thermoplastic materials with the best heat resistance. The melting point is 343℃, and the UL certified long-term use temperature is 260℃. Even when the temperature reaches 300℃, it can still maintain excellent mechanical properties.

2. PEEK thermal deformation temperature is 135~160℃, 20% glass fiber reinforced PEEK thermal deformation temperature is 286℃, 30% glass fiber reinforced thermal deformation temperature is 300℃.

3. PEEK has outstanding thermal aging properties. The tensile strength, quality and appearance of PEEK will not change significantly even if it is heated at 200℃ for 10,000 h. PEEK has excellent mechanical properties and is the most perfect material for the combination of toughness and rigidity among all resins. PEEK has high rigidity, and its strength and fatigue resistance can be compared with some metals and alloy materials. It can maintain high strength even at high temperature. The bending strength of PEEK can reach 24MPa at 200℃, and the bending strength and compressive strength can reach 12-13 MPa at 250℃, which is especially suitable for manufacturing components that work continuously at high temperature.

4. PEEK has small linear expansion coefficient (close to aluminum) and good dimensional stability. In addition, PEEK also has good creep resistance, can withstand great stress during the service life, and will not be extended significantly due to the extension of time. PEEK resin itself has excellent self-lubrication and wear resistance. After filling, the friction coefficient of the resin can be reduced to 0.15, and the wear amount is extremely low, which can realize oil-free lubrication work. It can be used in many harsh environments such as high temperature, high load and high speed. PEEK polymer and its composite materials have excellent abrasion resistance and are excellent bearing materials.

5. PEEK is resistant to almost any chemical except high concentrations of strong oxidizing acids such as sulfuric acid, and can maintain good chemical stability even at higher temperatures.

6. PEEK has good hydrolysis resistance, and the saturation water absorption rate at 23℃ is only 0.5%. Among all engineering plastics, PEEK has the best heat resistance to water and steam. It can be used for a long time at 200℃ steam, or for a short time at 300℃ high pressure steam.

7. PEEK resin is an ideal electrical insulator, which can maintain good electrical insulation performance under harsh working conditions such as high temperature, high pressure and high humidity. Usually, the volume resistivity can reach 10 15-16 Ω·cm, dielectric constant 3.2~3.3F/m, dielectric loss 0.0016 under the condition of 1kHz, breakdown voltage 17Kv, arc resistance 175V.

8. PEEK thermal decomposition temperature is high, high temperature fluidity is good, so it has good processing performance, can be processed in a variety of ways: injection molding, extrusion molding, molding, blow molding, melt spinning, rotary molding, powder spraying and so on.

9. PEEK's ability to resist γ radiation is very strong, which exceeds that of polystyrene with the best irradiation resistance among general resins. For example, the high-performance wire made of PEEK resin can maintain good insulation ability even when the radiation dose reaches 1100Mrad.

10. PEEK excellent flame retardant, with self-extinguish, without the use of any additives, 1.45㎜ thickness of PEEK sample flammability level of UL94V-0; The flammability level of PEEK sample with 3.2 mm thickness is UL94 5-V. Even when burning, the amount of smoke and the volume of toxic gas produced is very small, much lower than other kinds of resins.

11. PEEK resin has good peel resistance, so it can be made into thin coated wire or electromagnetic wire, and used under harsh conditions. Of all resins, PEEK has the best fatigue resistance.

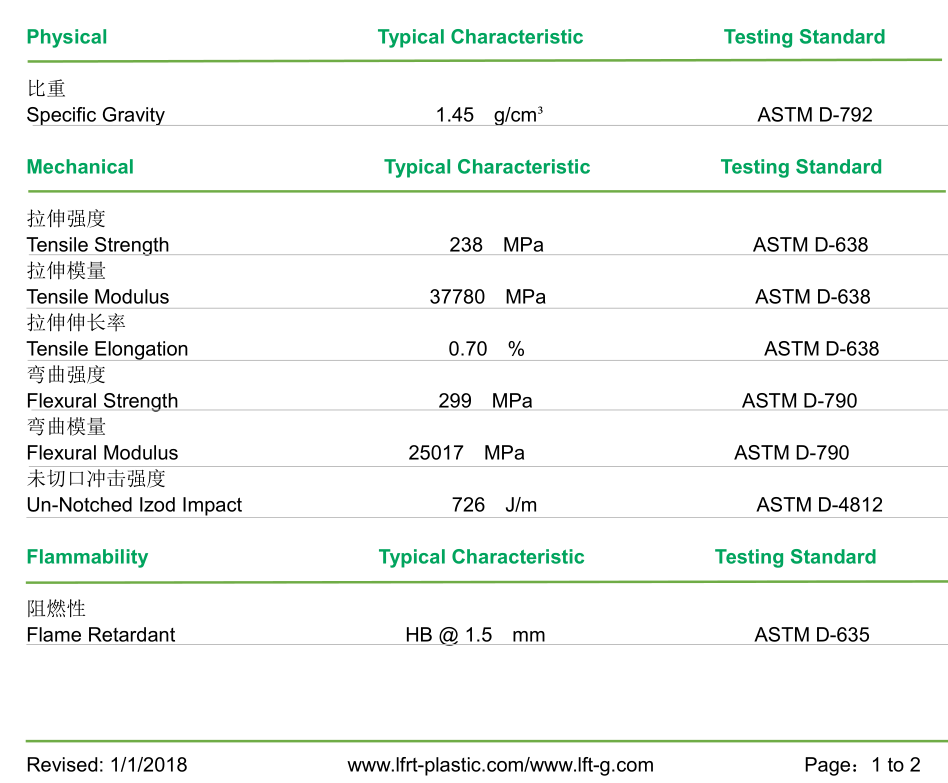

Product datasheet

Polyether ether ketone has the characteristics of high heat resistance, radiation resistance, corrosion resistance, good dimensional stability, excellent electrical properties, but also has excellent processing properties, easy injection molding, extrusion molding and cutting, is one of the best comprehensive performance of special engineering plastics, and polyimide and other top special engineering plastics in the top of the pyramid of plastic materials.

The datasheet is tested by our own lab, our products can reach these standard perfectly.

Product application

PEEK is widely used in automotive, military, medical, aviation, electrical and other industries.

① Aerospace

PEEK replaces aluminum and other metals for aircraft parts, reducing weight by up to 70 percent and improving fuel efficiency. At present, Boeing, Airbus and other companies have adopted PEEK material in large numbers.

The new Boeing 777 extended-range version is equipped with PEEK hubcaps. PEEK piping has now been designated for use in the cargo hold drainage system of the Airbus A350XWB. Airbus A350-A900 aircraft door fittings use a high modulus carbon fiber reinforced PEEK material.

In addition, some PEEK resin materials and its synthetic materials have obtained the quality certification of Commercial Aircraft Corporation of China LTD., and have been used in the manufacture of structural parts of the ARJ21 regional airliner. PEEK tubing has been applied to the Commercial Aircraft Corporation of China (COMAC) C919 mainline passenger aircraft for high voltage cable conduit instead of metal conduit.

In the field of aerospace, glass fiber reinforced PEEK material has been successfully applied to satellite lithium battery parts, high temperature insulation rings, etc., to solve the technical problems of common engineering plastics that can not meet the requirements of gas release, temperature resistance and insulation level.

② Automobile manufacturing

In the international market, the automobile industry is one of the most important application fields of PEEK resin. Using the good friction resistance and mechanical properties of PEEK, it can replace metal as the material for manufacturing engine inner cover, automobile bearings, gaskets, seals, clutch tooth rings and other parts. It is also used in automobile transmission, brake and air conditioning system, infinite transmission, vacuum pump blade, ABS brake valve, direction steering system, exhaust emission system, shaft sleeve, electric seat gear and so on.

③ Medical devices

PEEK has the advantages of non-toxicity, light weight, corrosion resistance, excellent biocompatibility, and is a potential biological prosthesis material. At present, the main application fields of polyether ether ketone in the repair and reconstruction of bone defects include polyether ether ketone interbody fusion apparatus, polyether ether ketone artificial bone joint (artificial hip joint, artificial knee joint, etc.), skull defect repair, jaw defect repair, spine/lumbar spine repair, oral repair and other bone defect repair. With the continuous research of these materials, various PEEK composites have been successfully developed and applied in the fields of oral implant, prosthesis, orthodontic and oral and maxillofacial surgery.

In addition, polyether ether ketone can be autoclaved for 3,000 cycles at 134℃, which is suitable for the manufacture of surgical and dental equipment requiring high sterilization requirements and repeated use. Coupled with its creep and hydrolytic resistance, it can be used to manufacture a variety of medical devices requiring high-temperature steam disinfection.

④ Electronic and electrical

Electronic and electrical field is also an important application field of polyether ether ketone resin. Polyether ether ketone has excellent dimensional stability, high purity, high mechanical properties, processing without waste gas production, excellent electrical properties, under high temperature, high humidity and other harsh conditions, polyether ether ketone insulation performance can still be maintained.

PEEK not only has excellent electrical insulation performance, but also good processing and chemical properties. The parts made with PEEK can withstand the high temperature environment of hot welding treatment, and can be processed in a variety of ways. Therefore, PEEK resin can be used to manufacture insulating film, connectors, printed circuit boards, high temperature connectors and so on.

⑤ Energy sector

PEEK can meet the high performance requirements of nuclear industry components. Radiation resistance is one of the key properties of materials used in nuclear power industry. Ordinary thermoplastic materials may become brittle when exposed to electromagnetic or particle ionizing radiation. Due to the energy-stable chemical structure of PEEK, parts made of PEEK materials can still work normally after being exposed to high doses of ionizing radiation, such as radiation resistance, excellent electrical properties at high temperatures, superior mechanical strength, good chemical corrosion resistance, low moisture absorption rate and excellent hydrolysis resistance. Make it the ideal choice of high performance component materials in the nuclear power industry.

PEEK はまた、高温、高圧、および化学的腐食環境向けに特別に設計されており、石油およびガス探査の範囲を拡大することができます。大規模な石油化学生産ラインの水素圧縮機および LPG 圧縮機用の円形およびメッシュ バルブの製造に使用できます。

なぜ私たちを選ぶのですか?

アモイLFT複合プラスチック有限公司は、20年間エンジニアリングプラスチックの改質を専門としています。新素材、新技術、ひとつひとつの素材を丁寧に行います。当社は、お客様のニーズに合わせて材料をカスタマイズできます。20年以上の技術経験の蓄積により、私たちは信頼できる変性材料メーカーです。お問い合わせへようこそ、カスタマイズされたソリューション、無料の見積もりを提供できます!

電子メール: sale02@lfrtplastic.com

連絡先番号: 13950095727