なぜプラスチックの耐摩耗性を改善する必要があるのですか?

プラスチック製品の広大なアプリケーションフィールドでは、耐摩耗性は、プラスチックのアプリケーション範囲とサービス寿命に決定的な役割を果たす重要なパフォーマンスインジケーターです。

プラスチックは、自動車製造、機械工学、電子機器、その他多くの分野で広く使用されているため、耐摩耗性の改善がますます重要になっています。 プラスチックの使用中に摩擦と摩耗を効果的に減らすために、現在2つの主なアプローチがあります。 潤滑物質の追加と補強材料。

ただし、潤滑剤はある程度摩擦を減らすことができますが、いくつかの欠点があります。

時間が経つにつれて、潤滑剤は老化しやすく、潤滑の有効性が低下し、定期的な追加とメンテナンスが必要です。 これにより、運用上のコストとメンテナンスワークロードが増加するだけでなく、内部部品を汚染し、機器の通常の操作に影響を与える可能性のあるほこりや破片を簡単に蓄積します。 したがって、補強材料を追加して、プラスチックの耐摩耗性と自己潤滑特性を改善することは、業界で徐々に好まれる選択肢になりました。

さて、詳しく見てみましょう プラスチックの耐摩耗性を改善するために使用される7つの一般的な強化材料.

ポリテトラフルオロエチレン(PTFE、テフロン)

ジスルフィドモリブデン(MO●)

黒鉛

グラファイトには、格子パターンに配置されたユニークな化学構造があります。 グラファイト分子が最小限の摩擦で互いに簡単にスライドできるようにするのは、この明確な構造です。 この耐摩耗性は、水分子の存在が材料間の摩擦を増加させるため、水環境では特に重要です。 グラファイトの特別な構造は、この摩擦を効果的に減少させます。

この特性により、グラファイトは理想的な耐摩耗性の添加物であり、水ポンプのハウジング、インピーラー、バルブシールなど、水に浸されたさまざまな用途で広く使用されています。 これらの用途では、グラファイトは水環境におけるプラスチックの耐摩耗性を大幅に高め、過酷な、湿潤、および水が豊富な状態で関連する機器の長期的な安定した動作を保証します。 メンテナンスと交換の頻度を削減し、使用コストを削減します。

ポリシロキサン

ポリシロキサン液体は、移動性摩耗耐性添加物です。 熱可塑性材料に追加すると、部品の表面にゆっくりと移動し、連続した薄膜が形成されます。 この薄膜は、目に見えない「鎧」のように機能し、外部の摩擦と摩耗から部分を効果的に保護します。 ポリシロキサンには幅広い粘度があります。 一般的に、ポリシロキサンの粘度が低いほど、液体が増加し、部品の表面により速く移動し、耐摩耗性が向上します。

ただし、粘度が低すぎると、部品からより簡単に蒸発し、すぐに消えてしまい、耐摩耗性が低下します。 したがって、ポリシロキサンを添加剤として選択する場合、その粘度は、最適な耐摩耗性性能を確保するために、特定の用途要件とプロセス条件に基づいて慎重に制御する必要があります。

ガラス繊維

ガラス繊維は、主にシリカで作られた無機的で非金属的な材料であり、その直径は通常、数ミクロンから20ミクロン以上の範囲です。 ガラス繊維には、優れた断熱特性、高耐熱性、強い耐食性、および高機械強度があります。 これらの特性により、プラスチックの補強材として一般的に使用されます。 ガラス繊維自体は脆く、耐摩耗性が低いですが、プラスチックを強化するために使用するとユニークな役割を果たします。

ガラス繊維は、プラスチックの分子構造内に頑丈な橋を構築し、個々の分子を緊密に接続するなど、ポリマー間に強い機械的結合を提供します。 これにより、熱可塑性構造の全体的な完全性が向上し、耐摩耗性が大幅に向上します。

ガラス繊維強化プラスチックは、ウォーターポンプ、水バルブ、ベアリング、シャフトスリーブ、ギア、サポート、ローラーなどのさまざまな機械部品で広く使用されています。 これらのアプリケーションでは、ガラス繊維強化プラスチックは、かなりの機械的ストレスと摩擦に耐えることができ、部品が長時間の動作よりも良好なパフォーマンスを維持し、機械装置の効率とサービスの寿命を大幅に向上させることができます。

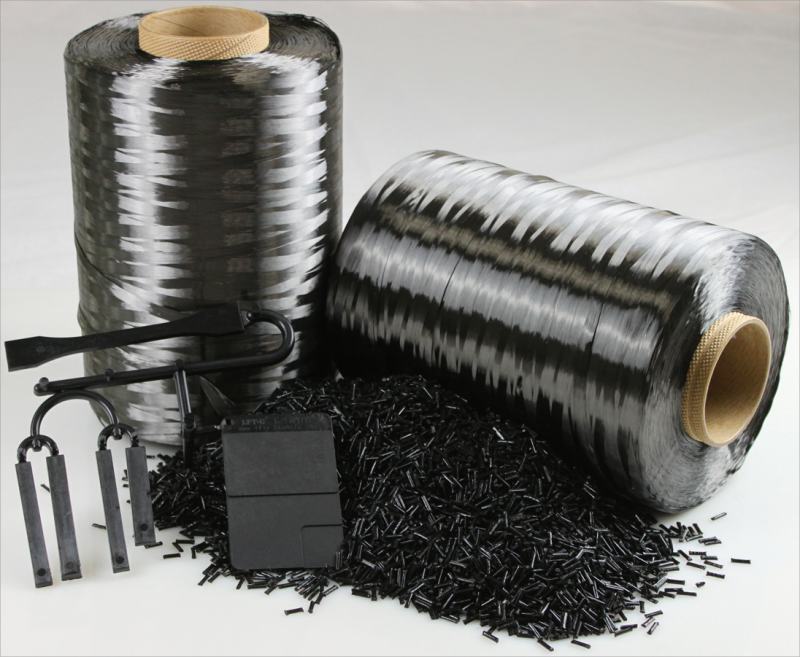

炭素繊維

炭素繊維は、ビスコースフィラメント、ポリアクリロニトリル繊維、アスファルト繊維などの材料で作られており、300〜1000°Cの範囲の温度で炭化されています。 ガラス繊維と同様に、炭素繊維は、プラスチック構造の全体的な完全性、耐摩耗性、耐荷重および摩擦抵抗を大幅に改善できます。

ただし、ガラス繊維とは異なり、炭素繊維はより柔らかく、研磨性の低い繊維であり、使用中に鉄または鋼の摩擦表面を傷つけることを妨げます。 自己潤滑特性を利用して、炭素繊維強化プラスチックは、航空機器やカセットレコーダー用のオイルフリーの潤滑型ベアリング、電気駆動式ディーゼル機関車用のオイルフリー潤滑ギアなどの特別な微妙なコンポーネントの生産に重要な役割を果たします(オイル漏れの原因となる潤滑剤の潤滑剤の潤滑剤による油を塗るためのオイルフリー潤滑ギア。

これらのアプリケーションは、炭素繊維強化プラスチックの耐摩耗性を完全に利用するだけでなく、その自己潤滑を利用して、潤滑油とメンテナンスコストの必要性を削減し、機器の安全性と信頼性を改善します。

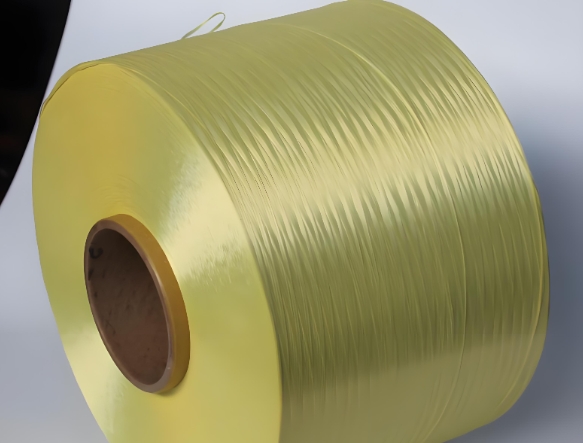

アラミッド繊維(芳香族ポリアミド繊維)

一般的にKevlarとして知られているAramid Fiberは、1960年代にデュポンが開発した新しいハイテク合成繊維です。 Aramid Fiberは、超高強度、高弾性率、高温抵抗、酸およびアルカリ抵抗、および軽量の特性を誇り、鋼線の5〜6倍の強度を備えています。 Aramidファイバーは、優れた耐摩耗性添加物でもあります。 ガラス繊維や炭素繊維と比較して、最も柔らかくて最小の研磨繊維です。

この特性は、特に交配部品の表面摩耗が懸念事項である場合、耐摩耗性のアプリケーションでアラミッド繊維がユニークな利点を与えます。 たとえば、アラミッド/高分子量ポリエチレンから作られた戦術ヘルメットの製造では、アラミッド繊維の適用はヘルメットの耐摩耗性を高めるだけでなく、衝撃時にエネルギーを効果的に分散させ、ユーザーの安全を保護できるようにします

タグ :