商品番号。:

PPA-NA-LCF30お支払い:

T/T or L/C (other payment ways also can be di製品の起源:

Xiamen, China色:

Original color (also can be customized)出荷ポート:

Xiamen, ChinaPPAとは何ですか?

PPA (Polyphthalamide) is polyphthalamide.

PPA is a kind of thermoplastic functional nylon with both semi-crystalline structure and non-crystalline structure. It is prepared by polycondensation of phthalic acid and phthalenediamine. It has excellent thermal, electrical, physical and chemical resistance and other comprehensive properties.

It still has excellent mechanical properties, including high rigidity, high strength, high dimensional accuracy, low warping and stability, fatigue resistance and creep resistance, under the harsh working environment of continuous high temperature, humidity, oil pollution and chemical corrosion at 200℃.

The main application is non-crystalline PPA. PPA has high hardness, excellent mechanical strength such as bending, tensile and impact at high temperature, and can resist tensile creep for a long time. Its rigidity and strength even exceed PPS and PEEK at the high temperature of 120℃. Especially suitable to replace die casting alloy to reduce cost.

PPA has higher thermal stability than PA46, better arc resistance and infrared reflow welding ability of CTI.

PPA has excellent resistance to gasoline, diesel, oil, mineral oil, transformer oil and other oils, even at high temperature of 150℃.

PPA is suitable for long-term outdoor use without reducing physical properties even in extreme climate conditions such as high UV radiation, high humidity and high temperature.

PPA resin is stronger and harder than fatty polyamides such as nylon 66; Less sensitive to water; Better thermal performance; And much better creep, fatigue and chemical resistance.

The vast majority of PPA resins are processed by traditional injection molding.

What is Long carbon fiber?

Long carbon fiber reinforced composites offer significant weight savings and provide optimum strength and stiffness properties in reinforced thermoplastics. The excellent mechanical properties of long carbon fiber reinforced company make it an ideal replacement for metals. Combined with the design and manufacturing advantages of injection molded thermoplastics, long carbon fiber composites simplify the re-imagining of components and equipment with demanding performance requirements. Its widespread use in aerospace and other advanced industries makes it a "high-tech" perception of consumers - you can use it to market products and create differentiation from competitors.

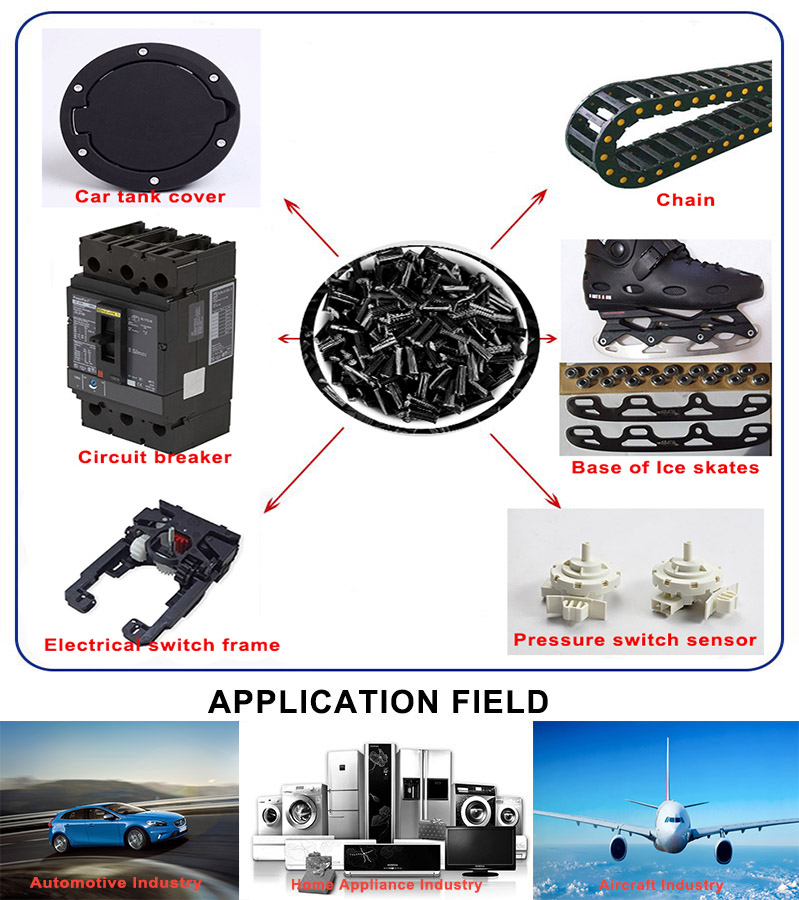

What is the application of PPA-LCF?

Suitable for high temperature, anti-static, high-strength components.

Other products can also ask for our advice. We have 24h 1V1 service for you.

Xiamen LFT composite plastic Co., ltd

Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length.

The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents. In particular, the carbon fiber LFT series produced by our company has broken the technical blockade of foreign countries. For domestic: automotive, military parts, firearms, aerospace, new energy, sports equipment and other fileds require high-performance thermoplastic special engineering plastics. And other new technology innovation industries provide product and technical support.