ガラス繊維強化材料の射出成形プロセスでは、 繊維浮遊 最も一般的な表面欠陥の一つです。部品のガラス繊維が露出することで、表面に凹凸が生じます。この問題は製品の外観を損なうだけでなく、塗装、コーティング、電気めっきなどの二次工程にも悪影響を及ぼす可能性があります。本日は、繊維浮きの根本原因を深く掘り下げ、効果的な解決策を探ります。

2. 射出成形プロセス要因の詳細な分析

充填速度が遅い:

繊維浮上を支える「見えない推進力」

主な問題: 充填が遅いと、ガラス繊維が成形部品の表面に移動します。

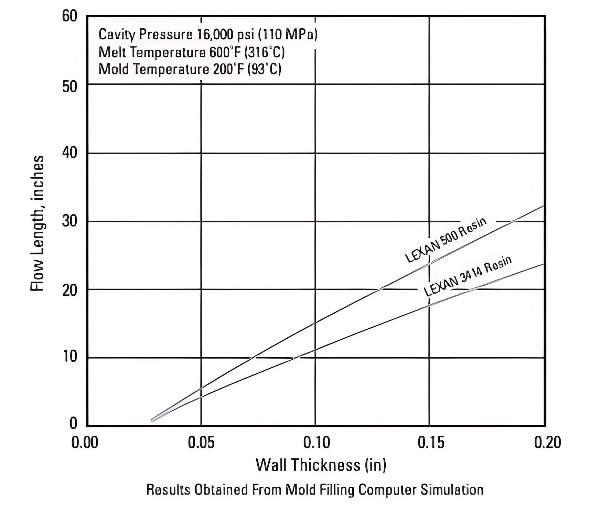

低融点:材料流動の「温度閾値」

主な発見: 溶融温度が 10 °C 低下するごとに、表面繊維浮上が 15~20% 増加します。

専門家の推薦:

バレルの設定値だけに頼るのではなく、溶融プローブを使用して実際の溶融温度を測定します。

溶融温度を推奨範囲の上限まで上げます(材料の劣化を避けながら)。

過度のファイバー破損を防ぐために、背圧の設定に注意してください。

実用的なヒント:

高温金型温度コントローラ(> 100 °C)または熱油システムを使用します。

誤用を避けるために、必要な金型温度コントローラのタイプを明確に示してください。

高温で操作する場合は、安全のために特別な注意が必要です。

3. 金型設計における重要な考慮事項

ベントシステム:スピードと品質のバランス

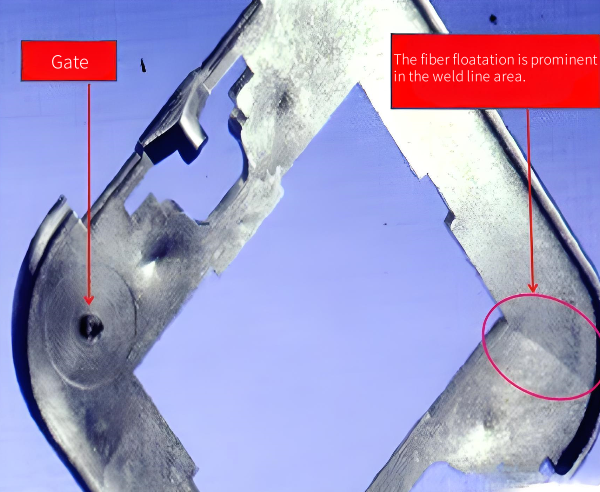

コアの競合: 高速充填には十分なベントが必要ですが、過度のベントはフラッシュや繊維の浮上欠陥 (例: ウェルド ライン、閉じ込められた空気) につながる可能性があります。

繊維浮上欠陥画像(ウェルドラインと閉じ込められた空気を含む)

ホットランナー温度: 見落とされがちな「熱の盲点」

よくある誤解: ホットランナーの温度はバレルの温度と矛盾して設定されます。

ベストプラクティス:

ホットランナーの温度を、材料の推奨溶融温度範囲内に設定します。

正確な温度制御には熱電対を使用します。

ゲート設計:流れの最初の障壁

設計ガイドライン:

突然の圧力上昇を引き起こす可能性があるゲートでの過度な制限を避けてください。

ゲートのサイズと位置は、材料の流動特性と一致する必要があります。

噴射マークや繊維の浮き上がりの悪化を防ぐため、ゲートが小さすぎることは避けてください。

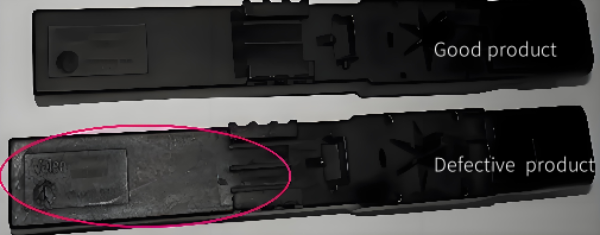

欠陥部品の画像:ジェット噴射による繊維浮上

概要:繊維浮上問題の解決策

優先原則:

まず主な原因 (通常はプロセス パラメータ) に対処し、次に二次的な要因に取り組みます。

体系的な思考:

プロセス、金型、設備、材料を網羅した統合ソリューションを開発します。

予防重視:

新しい金型の開発の初期段階で繊維浮上対策を検討してください。

データ駆動型アプローチ:

主要なパラメータのプロセス管理チャートを作成します。

継続的な改善:

繊維浮上問題に対する迅速な対応メカニズムと知識データベースを構築します。