長炭素繊維強化ポリエーテルエーテルケトンのぞき見 溶液含浸法により修復した。 長炭素繊維強化ポリエーテルエーテルケトンのぞき見 優れた性能を持つ特殊エンジニアリングプラスチックです。

-

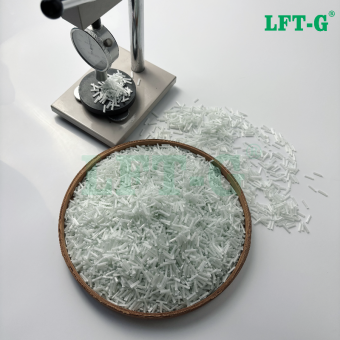

LFT-G ポリエーテルエーテルケトン充填長炭素繊維ポリマー超高強度PEEK-ロングカーボンファイバー ポリエーテルエーテルケトン(PEEK)は、ポリエーテルエーテルケトンの完全な英語名であり、優れた性能を備えた特殊エンジニアリングプラスチックであり、耐摩耗性、高温耐性、高強度および高弾性率、難燃性、放射線照射など、他の特殊エンジニアリングプラスチックに比べて多くの利点を持っています。耐性など。さらに、ポリエーテルエーテルケトン (PEEK) は優れた熱安定性と融点を超えるメルトフローを備えているため、熱可塑性プラスチックの典型的な加工特性も備えています。 PEEK樹脂は無毒で軽量、耐食性があり、人体の骨格に最も近い素材の一つで筋肉組織との親和性が高いため、金属の代わりに人骨を作るのによく使われます。炭素繊維強化 PEEK 複合材料は、靭性の弱点と衝撃強度のばらつきを補います。炭素繊維強化 PEEK 複合材料は、熱水、蒸気、溶剤、化学試薬などの条件下で高い機械的強度と加水分解安定性を示すことができ、高温蒸気滅菌を必要とするさまざまな医療機器の製造に使用できます。 PEEK-LCFの利点 PEEK は、高い剛性、良好な寸法安定性、低い線膨張係数を備えており、長期間にわたって大きな伸びを生じることなく大きな応力に耐えることができます。また、その低密度と優れた加工特性により、緻密さの要求が高い部品に適しています。これらの要素の中で、炭素繊維材料は PEEK の特性と重なり合います。カーボンファイバーは代表的な軽量素材であるだけでなく、機械的特性にも優れています。その結果、炭素繊維強化 PEEK 複合材料は、従来の金属材料と比較して重量を少なくとも 70% 削減できます。 PEEK 材料自体は非常に耐摩耗性が高く、炭素繊維との良好な界面結合により耐摩耗性がさらに向上します。炭素繊維強化 PEEK 複合部品とコバルト合金材料を使用した摩耗比較実験の結果は、次のことを示しています。 M-200 摩耗機を 400 rpm で 100 分間摩耗させたところ、炭素繊維強化 PEEK 複合材の表面が滑らかであることがわかりました。摩耗痕は小さく、炭素繊維は繊維が引き抜かれることなく PEEK とよく結合しました。対照的に、コバルト合金表面の摩耗痕跡は非常に明白で、多数の摩耗粒子が現れ、金属の内部不純物が目に見えます。 PEEK は、熱水、蒸気、溶剤、化学試薬などにおいて高い機械的強度と加水分解安定性を示します。 参考用のデータシート PEEK-LCF アプリケーション Q&A 1. 熱可塑性炭素繊維複合材料にはどのような種類がありますか? 炭素繊維熱可塑性複合材は、強化材として炭素繊維、マトリックスとして熱可塑性樹脂を用いた複合材です。炭素繊維の強化方法から、ロングカット炭素繊維(LCF)強化熱可塑性複合材、ショートカット炭素繊維(SCF)強化熱可塑性複合材、連続炭素繊維(CCF)強化熱可塑性複合材に分けることができます。 ロングカットカーボンファイバーとショートカットカーボンファイバーは主にカーボンファイバー材料の適用長さを指します。両者の間に厳密な固定的な区別はありません。一般に数ミリメートルから数センチメートルの間で、より一般的な仕様は6mm、12mmです。 、20mm、30mm、50mm。 炭素繊維熱可塑性複合材料は、熱可塑性樹脂に従って分類することもできます。 PE、PP、PVC などの一般的な熱可塑性樹脂は数多くあります。ただし、炭素繊維強化を含む熱可塑性樹脂複合材料は、航空宇宙、精密機器、その他の要求の厳しい作業環境で主に使用されるため、炭素繊維熱可塑性複合材料がより頻繁に製造されます。ポリエーテルエーテルケトン(PEEK)、PPS、ポリイミド(PI)、ポリエーテルイミド(PAI)などの中高級熱可塑性樹脂をマトリックスとして使用し、材料性能の最適化を実現します。 2. 熱可塑性炭素繊維複合材料はどのようにして低コストと環境保護を実現するのでしょうか? 熱可塑性炭素繊維複合材料は、ハイエンド機械の部品の製造に使用されます。機械加工性、真空成形性、プレス金型塑性性、曲げ加工性に優れています。 例えば、帝人は、特定のニーズに応じてプロセスにリサイクルプロセスを追加し、スタンピング後に熱可塑性炭素繊維複合材料�

- PEEK と長炭素繊維コンパウンド

- エンジニアリングプラスチックを覗かせる改質プラスチックペレット

- 厦門の熱可塑性プラスチック工場

- Peak CF30 射出成形 3D プリント

- PEEK ペレット lcf 30 ポリマー樹脂カーボンファイバー

- 自己負担ピークペレット補強

タグ :

-

アモイ LFT-G PEEK 自動車用高品質変性熱可塑性充填長炭素繊維ピークとは何ですか? ポリエーテルエーテルケトン (PEEK) は、剛性のベンゼン環、柔軟なエーテル結合、および分子鎖内の分子間力を促進できるカルボニル基を備えた半結晶性の熱可塑性ポリマー材料です。 PEEK は、耐摩耗性、電気絶縁性、耐放射性、化学的安定性、生体適合性、熱安定性に優れています。さらに、PEEK は再利用可能であり、回収率が高いです。 PEEK は、航空宇宙、電子・電気機器、生物医学、海洋保護、自動車産業などの分野で広く使用されています。 PEEK 材料は表面自由エネルギーが低い不活性材料であり、その機械的特性と摩擦特性は一部の特殊分野のニーズを満たすことができません。したがって、PEEK複合材料を改質してその総合的な特性を向上させる必要があります。 現在、充填改質と配合改質が PEEK 複合材料を製造する主な方法です。フィラーで修飾された強化材には主に繊維、無機粒子、ウィスカーが含まれます。ブレンド改質に使用されるポリマーは、PEEK と同様の極性と溶解性を備えている必要があります。界面改質方法により、界面の接着力が向上し、PEEK 複合材料の総合的な特性が向上します。 PEEK充填炭素長繊維とは何ですか? 充填システムとして、繊維は荷重の一部を効果的に運ぶことができ、繊維と PEEK の相乗作用により複合材料の総合的な性能を向上させることができます。炭素繊維とガラス繊維は、高強度、高弾性率、耐久性が高いため、フィラー改質複合材料として広く使用されています。長炭素繊維 (LCF) は、複合材料中の PEEK の結晶化を促進するための不均一核剤として使用でき、複合材料の機械的特性と摩擦学的特性を効果的に向上させることができます。 異なる長さの PEEK/CF 複合材料を射出成形によって調製し、その浸透特性と摩擦特性を研究しました。結果は、CF の添加により接触角が増加し、複合材料の親水性が低下することを示しています。しかし、複合材料の摩擦係数は減少し、耐摩擦性は向上します。長い炭素繊維 (LCF) は短い炭素繊維 (SCF) よりも摩擦係数を低減する効果が優れています。 参考のためのPEEKのTDS PEEK CFの応用 Q&A 1. 長炭素繊維素材の利点は何ですか? A: 熱可塑性 LFT 長炭素繊維材料は、高剛性、良好な衝撃強度、低反り、低収縮、導電性、静電気特性を備えており、その機械的特性はガラス繊維シリーズよりも優れています。長尺炭素繊維は、金属製品に代わる軽量かつ加工が容易な特性を持っています。 2. 長炭素繊維射出成形製品には特別なプロセス要件はありますか? A: 射出成形機のスクリューノズル、金型構造、射出成形プロセスに使用する長炭素繊維の要件を考慮する必要があります。長炭素繊維は比較的高価な材料であるため、選択の際にはコストパフォーマンスの問題を評価する必要があります。 3. 長繊維製品のコストは高くなります。リサイクル価値は高いですか? A: 熱可塑性 LFT 長繊維素材はリサイクルして再利用することができます。 私たちはあなたに以下を提供します: 1. LFTおよびLFRT材料の技術パラメータと最先端の設計 2. 金型正面の設計と推奨事項 3. 射出成形、押出成形等の技術サポートの提供

- PEEK樹脂LCFの低コスト削減

- ポリエーテルエーテルケトン充填LCF

- 代わりにメダルプラスチックピーク長寿命

- 射出成形プラティックピークキャットボンファイバー

- ロングカーボンファイバーシリーズピークフィラメント

- 自動車航空宇宙向けのより高い靭性ピークLCF

タグ :

-

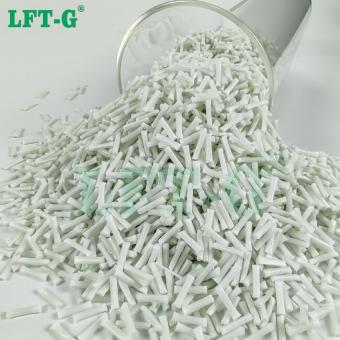

アモイ LFT ポリエーテルエーテルケトン CF 複合材料 20%-60% 高性能ナチュラルカラー製品グレード:一般グレード 繊維仕様: 20%-60% 製品特徴:難燃性、耐熱性、耐薬品性、低摩擦係数、良好な耐荷重性 製品用途: 航空、機械、エレクトロニクス、化学、自動車、その他のハイテク分野。

- 耐荷重性に優れたポリエーテルエーテルケトン

- 自社工場で低摩擦係数を実現

- 自社工場製のピュアでバージンな覗き見

- 幅広い用途のピーク産業資材強化ピーク

- カスタマイズされた素材は靭性を発揮します カーボン

- ガラス長繊維はリサイクル可能 航空宇宙産業のピーク

タグ :

-

アモイ LFT ポリエーテルエーテルケトン LCF 複合材料の高性能ナチュラルカラー製品グレード:一般グレード 繊維仕様: 20%-60% 製品特徴:難燃性、耐熱性、耐薬品性、低摩擦係数、良好な耐荷重性 製品用途: 航空、機械、エレクトロニクス、化学、自動車、その他のハイテク分野。もっと見る

-

LFTバージンコンポジットPEEK長炭素繊維強化高強度と剛性PEEK-ロングカーボンファイバー ポリエーテルエーテルケトン(PEEK)は、ポリエーテルエーテルケトンの完全な英語名であり、優れた性能を備えた特殊エンジニアリングプラスチックであり、耐摩耗性、高温耐性、高強度および高弾性率、難燃性、放射線照射など、他の特殊エンジニアリングプラスチックに比べて多くの利点を持っています。耐性など。さらに、ポリエーテルエーテルケトン (PEEK) は優れた熱安定性と融点を超えるメルトフローを備えているため、熱可塑性プラスチックの典型的な加工特性も備えています。 PEEK樹脂は無毒で軽量、耐食性があり、人体の骨格に最も近い素材の一つで筋肉組織との親和性が高いため、金属の代わりに人骨を作るのによく使われます。炭素繊維強化 PEEK 複合材料は、靭性の弱点と衝撃強度のばらつきを補います。炭素繊維強化 PEEK 複合材料は、熱水、蒸気、溶剤、化学試薬などの条件下で高い機械的強度と加水分解安定性を示すことができ、高温蒸気滅菌を必要とするさまざまな医療機器の製造に使用できます。 PEEK-LCFの利点 PEEK は、高い剛性、良好な寸法安定性、低い線膨張係数を備えており、長期間にわたって大きな伸びを生じることなく大きな応力に耐えることができます。また、その低密度と優れた加工特性により、緻密さの要求が高い部品に適しています。これらの要素の中で、炭素繊維材料は PEEK の特性と重なり合います。カーボンファイバーは代表的な軽量素材であるだけでなく、機械的特性にも優れています。その結果、炭素繊維強化 PEEK 複合材料は、従来の金属材料と比較して重量を少なくとも 70% 削減できます。 PEEK 材料自体は非常に耐摩耗性が高く、炭素繊維との良好な界面結合により耐摩耗性がさらに向上します。炭素繊維強化 PEEK 複合部品とコバルト合金材料を使用した摩耗比較実験の結果は、次のことを示しています。 M-200 摩耗機を 400 rpm で 100 分間摩耗させたところ、炭素繊維強化 PEEK 複合材の表面が滑らかであることがわかりました。摩耗痕は小さく、炭素繊維は繊維が引き抜かれることなく PEEK とよく結合しました。対照的に、コバルト合金表面の摩耗痕跡は非常に明白で、多数の摩耗粒子が現れ、金属の内部不純物が目に見えます。 PEEK は、熱水、蒸気、溶剤、化学試薬などにおいて高い機械的強度と加水分解安定性を示します。 参考用のデータシート PEEK-LCF アプリケーション Q&A 1. 熱可塑性炭素繊維複合材料にはどのような種類がありますか? 炭素繊維熱可塑性複合材は、強化材として炭素繊維、マトリックスとして熱可塑性樹脂を用いた複合材です。炭素繊維の強化方法から、ロングカット炭素繊維(LCF)強化熱可塑性複合材、ショートカット炭素繊維(SCF)強化熱可塑性複合材、連続炭素繊維(CCF)強化熱可塑性複合材に分けることができます。 ロングカットカーボンファイバーとショートカットカーボンファイバーは主にカーボンファイバー材料の適用長さを指します。両者の間に厳密な固定的な区別はありません。一般的に数ミリメートルから数センチメートルの間であり、より一般的な仕様は6mm、12mmです。 、20mm、30mm、50mm。 炭素繊維熱可塑性複合材料は、熱可塑性樹脂に従って分類することもできます。PE、PP、PVC など、一般的な熱可塑性樹脂は数多くあります。ただし、炭素繊維強化を含む熱可塑性樹脂複合材料は、航空宇宙、精密機器、その他の要求の厳しい作業環境で主に使用されるため、炭素繊維熱可塑性複合材料がより頻繁に製造されます。ポリエーテルエーテルケトン(PEEK)、PPS、ポリイミド(PI)、ポリエーテルイミド(PAI)などの中高級熱可塑性樹脂をマトリックスとして使用し、材料性能の最適化を実現します。 2. 熱可塑性炭素繊維複合材料はどのようにして低コストと環境保護を実現するのでしょうか? 熱可塑性炭素繊維複合材料は、ハイエンド機械の部品の製造に使用されます。機械加工性、真空成形性、プレス金型塑性性、曲げ加工性に優れています。 例えば、帝人は、特定のニーズに応じてプロセスにリサイクルプロセスを追加し、スタンピング後に熱可塑性炭素繊維複�

- 長い炭素繊維を使用したPEEK

- 変性プラスチックペレット 特殊エンジニアリングプラスチック

- ピークCF30の代わりに金属製の要求の高いもの

- PEEK ペレット lcf 30 ポリマー

- 自己所有のピークペレット

タグ :

-

LFT-G ポリエーテルエーテルケトン充填長炭素繊維ポリマー超高強度PEEK-ロングカーボンファイバー ポリエーテルエーテルケトン(PEEK)は、ポリエーテルエーテルケトンの完全な英語名であり、優れた性能を備えた特殊エンジニアリングプラスチックであり、耐摩耗性、高温耐性、高強度および高弾性率、難燃性、放射線照射など、他の特殊エンジニアリングプラスチックに比べて多くの利点を持っています。耐性など。さらに、ポリエーテルエーテルケトン (PEEK) は優れた熱安定性と融点を超えるメルトフローを備えているため、熱可塑性プラスチックの典型的な加工特性も備えています。 PEEK樹脂は無毒で軽量、耐食性があり、人体の骨格に最も近い素材の一つで筋肉組織との親和性が高いため、金属の代わりに人骨を作るのによく使われます。炭素繊維強化 PEEK 複合材料は、靭性の弱点と衝撃強度のばらつきを補います。炭素繊維強化 PEEK 複合材料は、熱水、蒸気、溶剤、化学試薬などの条件下で高い機械的強度と加水分解安定性を示すことができ、高温蒸気滅菌を必要とするさまざまな医療機器の製造に使用できます。 PEEK-LCFの利点 PEEK は、高い剛性、良好な寸法安定性、低い線膨張係数を備えており、長期間にわたって大きな伸びを生じることなく大きな応力に耐えることができます。また、その低密度と優れた加工特性により、緻密さの要求が高い部品に適しています。これらの要素の中で、炭素繊維材料は PEEK の特性と重なり合います。カーボンファイバーは代表的な軽量素材であるだけでなく、機械的特性にも優れています。その結果、炭素繊維強化 PEEK 複合材料は、従来の金属材料と比較して重量を少なくとも 70% 削減できます。 PEEK 材料自体は非常に耐摩耗性が高く、炭素繊維との良好な界面結合により耐摩耗性がさらに向上します。炭素繊維強化 PEEK 複合部品とコバルト合金材料を使用した摩耗比較実験の結果は、次のことを示しています。 M-200 摩耗機を 400 rpm で 100 分間摩耗させたところ、炭素繊維強化 PEEK 複合材の表面が滑らかであることがわかりました。摩耗痕は小さく、炭素繊維は繊維が引き抜かれることなく PEEK とよく結合しました。対照的に、コバルト合金表面の摩耗痕跡は非常に明白で、多数の摩耗粒子が現れ、金属の内部不純物が目に見えます。 PEEK は、熱水、蒸気、溶剤、化学試薬などにおいて高い機械的強度と加水分解安定性を示します。 参考用のデータシート PEEK-LCF アプリケーション Q&A 1. 熱可塑性炭素繊維複合材料にはどのような種類がありますか? 炭素繊維熱可塑性複合材は、強化材として炭素繊維、マトリックスとして熱可塑性樹脂を含む複合材です。炭素繊維の強化方法から、ロングカット炭素繊維(LCF)強化熱可塑性複合材、ショートカット炭素繊維(SCF)強化熱可塑性複合材、連続炭素繊維(CCF)強化熱可塑性複合材に分けることができます。 ロングカットカーボンファイバーとショートカットカーボンファイバーは主にカーボンファイバー材料の適用長さを指します。両者の間に厳密な固定的な区別はありません。一般に数ミリメートルから数センチメートルの間であり、より一般的な仕様は6mm、12mmです。 、20mm、30mm、50mm。 炭素繊維熱可塑性複合材料は、熱可塑性樹脂に従って分類することもできます。PE、PP、PVC などの一般的な熱可塑性樹脂は数多くあります。ただし、炭素繊維強化を含む熱可塑性樹脂複合材料は、航空宇宙、精密機器、その他の要求の厳しい作業環境で主に使用されるため、炭素繊維熱可塑性複合材料がより頻繁に製造されます。ポリエーテルエーテルケトン(PEEK)、PPS、ポリイミド(PI)、ポリエーテルイミド(PAI)などの中高級熱可塑性樹脂をマトリックスとして使用し、材料性能の最適化を実現します。 2. 熱可塑性炭素繊維複合材料はどのようにして低コストと環境保護を実現するのでしょうか? 熱可塑性炭素繊維複合材料は、ハイエンド機械の部品の製造に使用されます。機械加工性、真空成形性、プレス金型塑性性、曲げ加工性に優れています。 例えば、帝人は、特定のニーズに応じてプロセスにリサイクルプロセスを追加し、スタンピング後に熱可塑性炭素繊維複合材�もっと見る

-

アモイ LFT-G 長炭素繊維強化 PEEK 複合射出成形軽量自動車部品用の PEEK 充填長炭素繊維強化熱可塑性樹脂。

- 炭素繊維PEEK顆粒航空宇宙自動車部品

- 炭素繊維複合材ピーク顆粒

- プラスチックのピーク カーボンファイバーポリマーのピーク 樹脂

- 黒い色が覗く炭素繊維顆粒

- 黒い色が覗くカーボンファイバープラスチック

- ピークカーボンファイバー強化ペレット

タグ :

-

LFT-G PEEK ポリエーテルエーテルケトン複合長炭素繊維熱可塑性樹脂PEEK-LCF ポリエーテルエーテルケトン(略称PEEK)は、機械的、耐熱性、耐薬品性に優れているだけでなく、摩擦係数が低く、軸受のかみ合いが良好で、軸受容量と耐摩耗性においてポリテトラフルオロエチレン(PTFE)に次ぐ優れた自己潤滑材料です。 PTFEよりも性能が優れており、無潤滑、低速、高負荷、高温、多湿、汚染、腐食などの過酷な環境に特に適しています。これに基づいて、カーボンファイバーの添加は機械的特性を向上させるだけでなく、摩擦性能にも重要な影響を与えます。 30% 炭素繊維強化 PEEK 複合材の引張強度は室温で 2 倍になり、150℃では 3 倍に達しました。同時に、強化複合材料の衝撃強度、曲げ強度、弾性率も大幅に向上し、伸びが大幅に減少し、熱変形温度は300℃を超える可能性があります。複合材料の衝撃エネルギー吸収率は、複合材料の衝撃性能に直接影響します。炭素繊維強化 PEEK 複合材は、最大 180kJ/kg の比エネルギー吸収容量を示します。 カーボンファイバーの強化効果により、PEEK の熱軟化にも抵抗し、ある程度の強度を持つ非常に高い転写フィルムを形成し、接触領域を効果的に保護できます。したがって、炭素繊維強化 PEEK 複合材の摩擦係数と比摩耗率は、純粋な PEEK よりも大幅に低くなります。同じ実験条件下で、炭素繊維強化PEEK複合材料の摩擦および耐摩耗性はガラス繊維PEEK複合材料よりも明らかに優れており、材料の耐摩耗性に対する炭素繊維の改善効果はガラス繊維の5倍以上です。同じ用量で。炭素繊維強化 PEEK 複合材料は部品製造に使用されており、金属やセラミック材料の表面亀裂を効果的に回避でき、その優れたトライボロジー特性は超高分子量ポリエチレンの特性をも上回ります。 TDS 応用 炭素長繊維強化PEEKは、主に以下の4分野に応用されています。 1. 電子・電気機器 PEEKは、高温、高圧、高湿などの過酷な環境下でも良好な電気絶縁性を維持でき、変形しない特性を持っています。使用温度範囲が広いため、電子・電気機器分野で理想的な電気絶縁材料として使用されています。炭素繊維で強化されたポリエーテルエーテルケトンは、機械的性質、耐薬品性、耐放射線性、耐高温性がさらに向上し、その応用分野がさらに拡大しました。 2.航空宇宙用 ポリエーテルエーテルケトンPEEKは、低密度で加工性が良いという利点があるため、需要の高い部品に直接加工することが容易であり、炭素繊維強化ポリエーテルエーテルケトン複合材料はポリエーテルエーテルケトンの全体的な性能をさらに向上させます。そのため、航空機製造での使用が増えています。たとえば、ボーイングの 757-200 シリーズ航空機のフェアリングは炭素繊維強化 PEEK で作られています。さらに、オランダ、アムステルダムの Gereedschappen Fabrick は、30% の炭素繊維強化 PEEK 複合材料を使用してより大きなコンポーネントを構築し、その機械的特性が航空機のバランス装置に使用できることを実証しました。 3. 自動車 自動車のエネルギー消費量は車両重量と密接に関係しています。自動車の軽量化は、燃料消費量や排気ガスの削減につながるだけでなく、動力性能や安全性の向上にもつながり、省エネに効果的です。構造の軽量設計に加えて、軽量素材の使用はより直接的な方法です。低密度、優れた性能、便利な技術という利点により、炭素繊維強化ポリエーテルエーテルケトン複合材料は自動車産業でますます頻繁に使用されており、鋼をプラスチックに置き換える大きな可能性を示しています。たとえば、ロバート ボッシュ GmbH は、ABS の機能として金属の代わりに炭素繊維強化 PEEK を使用しています。軽量の複合部品により慣性モーメントが減少し、これにより反応時間が最小限に抑えられ、システム全体の反応性が大幅に向上し、以前に使用されていた金属部品と比較してコストが削減されます。 4. ヘルスケア 現在利用可能な医療用高分子材料は、ポリテトラフルオロエチレン、ポリ乳酸、シリコーンゴムなど数十種類ありますが、生体医学の観点からは副作用があり、使用には適さない材料であり、毒性のないPEEK樹脂が使用されています。 、軽量、もっと見る

-

アモイ LFT-G PEEK 自動車用高品質変性熱可塑性充填長炭素繊維ピークとは何ですか? ポリエーテル エーテル ケトン (PEEK) は、剛性のベンゼン環、柔軟なエーテル結合、および分子鎖内の分子間力を促進できるカルボニル基を備えた半結晶性の熱可塑性ポリマー材料です。PEEK は、耐摩耗性、電気絶縁性、耐放射性、化学的安定性、生体適合性、熱安定性に優れています。さらに、PEEK は再利用可能であり、回収率が高いです。 PEEK は、航空宇宙、電子・電気機器、生物医学、海洋保護、自動車産業などの分野で広く使用されています。PEEK 材料は表面自由エネルギーが低い不活性材料であり、その機械的特性と摩擦特性は一部の特殊分野のニーズを満たすことができません。したがって、PEEK複合材料を改質してその総合的な特性を向上させる必要があります。 現在、充填改質と配合改質が PEEK 複合材料を製造する主な方法です。フィラーで修飾された強化材には主に繊維、無機粒子、ウィスカーが含まれます。ブレンド改質に使用されるポリマーは、PEEK と同様の極性と溶解性を備えている必要があります。界面改質方法により、界面の接着力が向上し、PEEK 複合材料の総合的な特性が向上します。 PEEK充填炭素長繊維とは何ですか? 充填システムとして、繊維は荷重の一部を効果的に運ぶことができ、繊維と PEEK の相乗作用により複合材料の総合的な性能を向上させることができます。炭素繊維とガラス繊維は、高強度、高弾性率、耐久性が高いため、フィラー改質複合材料として広く使用されています。長炭素繊維 (LCF) は、複合材料中の PEEK の結晶化を促進するための不均一核剤として使用でき、複合材料の機械的特性と摩擦学的特性を効果的に向上させることができます。 異なる長さの PEEK/CF 複合材料を射出成形によって調製し、その浸透特性と摩擦特性を研究しました。結果は、CF の添加により接触角が増加し、複合材料の親水性が低下することを示しています。しかし、複合材料の摩擦係数は減少し、耐摩擦性は向上します。長い炭素繊維 (LCF) は短い炭素繊維 (SCF) よりも摩擦係数を低減する効果が優れています。 参考のためのPEEKのTDS PEEK CFの応用 Q&A 1. 長炭素繊維素材の利点は何ですか? A: 熱可塑性 LFT 長炭素繊維材料は、高剛性、良好な衝撃強度、低反り、低収縮、導電性、静電気特性を備えており、その機械的特性はガラス繊維シリーズよりも優れています。長尺炭素繊維は、金属製品に代わる軽量かつ加工が容易な特性を持っています。 2. 長炭素繊維射出成形製品には特別なプロセス要件はありますか? A: 射出成形機のスクリューノズル、金型構造、射出成形プロセスに使用する長炭素繊維の要件を考慮する必要があります。長炭素繊維は比較的高価な材料であるため、選択の際にはコストパフォーマンスの問題を評価する必要があります。 3. 長繊維製品のコストは高くなります。リサイクル価値は高いですか? A: 熱可塑性 LFT 長繊維素材はリサイクルして再利用することができます。 私たちはあなたに以下を提供します: 1. LFTおよびLFRT材料の技術パラメータと最先端の設計 2. 金型正面の設計と推奨事項 3. 射出成形、押出成形等の技術サポートの提供もっと見る

-

アモイ LFT ポリエーテルエーテルケトン CF 複合材料 20%-60% 高性能ナチュラルカラー製品グレード:一般グレード 繊維仕様: 20%-60% 製品特徴:難燃性、耐熱性、耐薬品性、低摩擦係数、良好な耐荷重性 製品用途: 航空、機械、エレクトロニクス、化学、自動車、その他のハイテク分野。もっと見る

-

LFT-G コンポジット PEEK 長炭素繊維 要求の厳しい用途向けの 30% ナチュラルカラー製品グレード:一般グレード 繊維仕様: 20%-60% 製品特徴:難燃性、耐熱性、耐薬品性、低摩擦係数、良好な耐荷重性 製品用途: 航空、機械、エレクトロニクス、化学、自動車、その他のハイテク分野。

- 低い摩擦係数

- 自社工場で製造された優れた機械的および耐薬品性の特性が覗く

- 幅広い用途のベアリング、ピストン部品、ポンプ PEEK

- カスタマイズされたピーク長さ 10 ~ 12 mm

- 高温に保持される長炭素繊維

タグ :

-

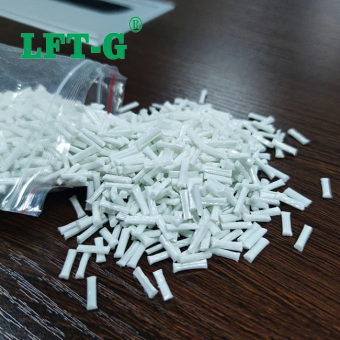

LFT-G 航空宇宙用 PEEK 高強度と剛性の射出成形ペレットPEEKのご紹介 PEEKはポリエーテルエーテルケトンとも呼ばれ、高性能半結晶性プラスチックであり、このようなプラスチックは優れた耐薬品性、機械的強度、寸法安定性などの優れた性能を備えており、性能に応じてさまざまなシリーズに分けられます。 PEEK 材料の最も一般的な分類は、PEEK 純粋材料、ガラス繊維または炭素繊維修飾です。 PEEK Pure 素材 PEEK Pure は破断点伸びが 15% であるにもかかわらず、その高い靭性にもかかわらず、弾性率はわずか 4,200mpa で、プラスチックの中で最も低いことがわかります。この比較的低い弾性率は、純粋な PEEK が他の PEEK 改質剤よりも「柔らかく」、耐摩耗性が低いことを意味します。したがって、摩擦作業条件で純粋な PEEK を使用する場合は、材料の摩耗による材料の損失に注意してください。 PEEK充填長炭素繊維素材 PEEK LCF30 は、PEEK 純粋材料をベースにした 30% 長い炭素繊維充填プラスチックです。炭素繊維は、材料の最大の靭性を維持しながら、PEEK 純粋材料と比較して弾性率を高めます。PEEK CF30 は、非常に高いレベルの剛性を維持し、比較的高い靭性。 さらに、長炭素繊維変性 PEEK は優れた耐摩耗性と非常に良好な摩擦特性を示します。PEEK LCF30 は PEEK LGF30 に比べて耐摩耗性に優れています。長い炭素繊維がより効率的に熱を伝導します。したがって、PEEK LCF30 はスライド用途に適しています。 PEEK 純粋樹脂と同様に、PEEK LCF30 は蒸気や沸騰水中で優れた耐加水分解性を備えています。 LCFとSCFの違い ステープルファイバーはカットセクションファイバーとも呼ばれ、ステープルファイバーは主に化学的な長い繊維を短い繊維のセクションに切断することによって得られ、形成される繊維は天然繊維とほぼ同じ長さになります。通常の状況では、35 ~ 150 mm の間がステープルファイバーの長さと呼ばれます。 繊維で作られた複合材料では、繊維がマトリックスから切断または引っ張られ、そのような引っ張りプロセスは、繊維の特定の長さの範囲で、繊維が長ければ長いほど、負荷によって提供されるエネルギーの吸収に役立ちます。エネルギーの吸収が大きくなり、その強度も大きくなります。また、同じ体積量であれば、単繊維が長くなり、繊維根の数が少なくなるため、繊維端に発生する応力集中が少なくなり、材料が破壊されにくくなります。実用化のフィードバックの結果、6mm~24mmの長炭素繊維強化熱可塑性複合材料は、短繊維に比べて優れた諸特性を有していることがわかった。 さらに、炭素繊維強化複合材料は、摩擦プロセスにおいて繊維本体が潤滑において重要な役割を果たし、長距離炭素繊維はより持続可能で安定した潤滑が可能であるため、摩擦係数が低くなり、摩耗が少なくなり、より細かい研磨破片。このような利点により、長炭素繊維強化熱可塑性複合材料は高周波や負荷を恐れず、実際の用途ではるかに優れた性能を発揮します。 PEEK-LCF材料の応用

- 電気アクセサリ用長炭素繊維強化PEEK

- 黒色ペレットPEEKサンプルあり

- PEEK LCFR 自動車部品 3D プリンター

- 射出成形用PEEK自動車部品ポリマー

- 金属の代わりに軽量のPEEKを使用

- 複合ペレット ポリマー顆粒

タグ :

Eメール

Eメール 日本語

日本語 English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 한국의

한국의 中文

中文